Introduction of Oilseeds Processing Solution

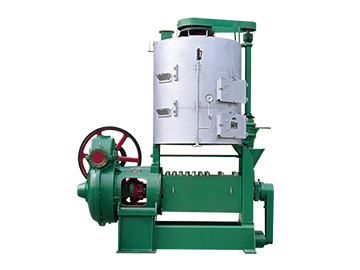

We are engaged in oil pretreatment, pressing, leaching, oil refining and supporting engineering design, equipment manufacturing and installation, engineering contracting, new product development, deep processing of oil by-products, chemical equipment manufacturing, pressure pipeline design and installation.

We meticulously design and implement processing lines tailored to the unique production conditions and demands of our clients. Adhering steadfastly to industry standards, we leverage our company's proprietary patented technologies and core equipment to ensure that our production lines operate with stability, easy to maintain, energy-efficient, and environmentally friendly.

Oilseeds Processing

oilseeds

oils

Comprehensive Oilseed Processing: Diverse and Specialized

We have a complete engineering technology service industry chain for oil processing (pre-pressing - extraction - refining - small packaging - oil tank area);

Engineering technology scale (single-line production capacity: pretreatment 4000t/d; extraction 4000t/d; refining 1000t/d);

Achieve full coverage of processing varieties (soybean, rapeseed, peanut, cottonseed, rice bran, tea seed, corn germ, walnut and other special varieties);

Possess palm oil fractionation technology, vacuum dry condensation system, drag chain extractor, etc. that represent the industry's leading level.

Engineering technology scale (single-line production capacity: pretreatment 4000t/d; extraction 4000t/d; refining 1000t/d);

Achieve full coverage of processing varieties (soybean, rapeseed, peanut, cottonseed, rice bran, tea seed, corn germ, walnut and other special varieties);

Possess palm oil fractionation technology, vacuum dry condensation system, drag chain extractor, etc. that represent the industry's leading level.

Oil Processing Projects

You Might Also Be Interested In

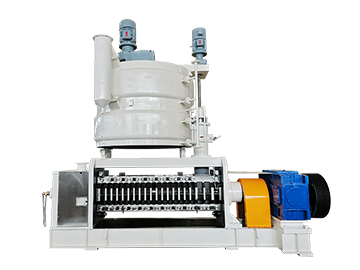

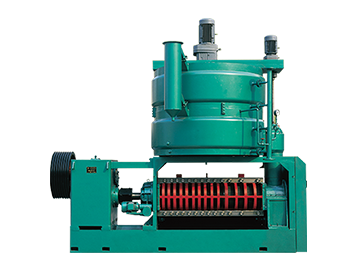

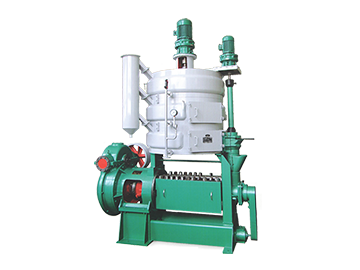

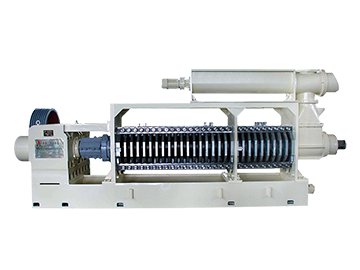

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry