Introduction of Wheat Flour Milling Process

The key to superior grain milling lies in process optimization - implementing precise methods to remove impurities and strategically separate grain components. This systematic approach enhances product quality while maximizing yield efficiency. Modern automation and digital monitoring systems further elevate your operation, ensuring robust food safety protocols and complete supply chain traceability.

Our company offers customized project solutions from the concept stage to the production stage, keeping the costs at a minimum, and assuring on-time delivery.Trusted by clients worldwide, we deliver high quality, personalized solutions to address challenges across the grain processing industry value chain. Our longevity and proven success come from a commitment to innovation, sustainability and achieving maximum value for our customers.

Wheat Milling Production Process

Wheat

Flour

Flour Milling Solutions

Wheat milling is a sophisticated process that integrates multiple stages of analyzing, blending, grinding, sifting, and blending again, a variety of wheat.Hard wheat varieties are engineered for optimal bread production, while durum wheat is exclusively processed for premium pasta products. Asian noodle production demands a carefully calibrated blend of hard and soft wheat varieties. The distinct properties of soft wheat make it ideal for a diverse portfolio of products, including pastries, crackers, cereals, and various baked goods.

Our comprehensive portfolio spans:

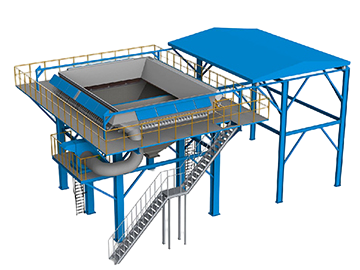

Fully integrated turnkey flour mill installations

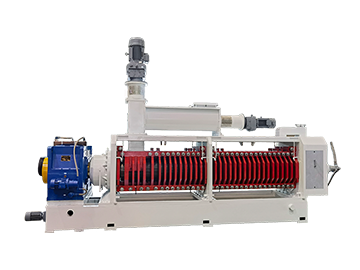

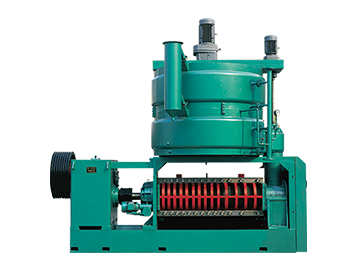

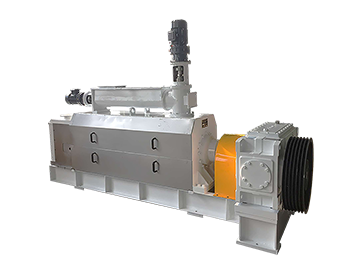

Specialized precision machinery for every production stage

Customized engineering solutions tailored to diverse client requirements

Our commitment extends beyond equipment supply, offering holistic solutions that optimize productivity, efficiency, and quality across the entire flour production ecosystem. From conceptualization to implementation, COFCO Technology & Industry transforms wheat processing through state-of-the-art technological solutions that meet the evolving demands of global food manufacturing.

Capacity Spectrum:

Compact 100 tons per day industrial installations

Mid-scale processing plants ranging 500-1000 tons daily

Large-scale manufacturing facilities up to 2000 tons per day

Interior view for flour mill with concrete structure building

Floor Plan 1 Floor Plan 2 Floor Plan 3

Floor Plan 4 Floor Plan 5 Floor Plan 6

Our comprehensive portfolio spans:

Fully integrated turnkey flour mill installations

Specialized precision machinery for every production stage

Customized engineering solutions tailored to diverse client requirements

Our commitment extends beyond equipment supply, offering holistic solutions that optimize productivity, efficiency, and quality across the entire flour production ecosystem. From conceptualization to implementation, COFCO Technology & Industry transforms wheat processing through state-of-the-art technological solutions that meet the evolving demands of global food manufacturing.

Capacity Spectrum:

Compact 100 tons per day industrial installations

Mid-scale processing plants ranging 500-1000 tons daily

Large-scale manufacturing facilities up to 2000 tons per day

Interior view for flour mill with concrete structure building

Floor Plan 1 Floor Plan 2 Floor Plan 3

Floor Plan 4 Floor Plan 5 Floor Plan 6

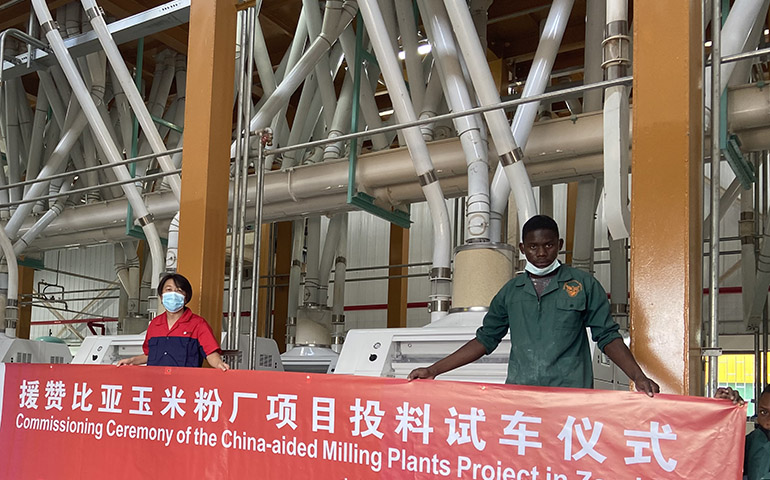

Flour Mill Projects Wolrdwide

Wheat Milling Plant Video

You Might Also Be Interested In

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry