Introduction of Rice Milling Process

According to the different characteristics of rice and quality criteria around the world, based on the needs of customers and the market, COFCO Technology & Industry provides you with advanced, flexible, reliable rice processing solutions with optimized configuration for easy operation and maintenance.

We are engaged in engineering consulting, engineering design, equipment procurement, and overall project contracting for large and medium-sized rice processing production lines. We offer comprehensive services from project conception to completion, ensuring seamless integration and optimization of every stage in the rice processing industry.

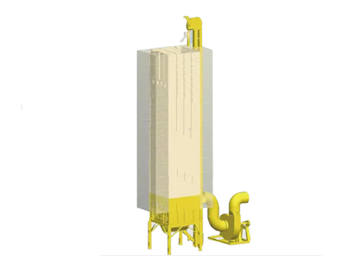

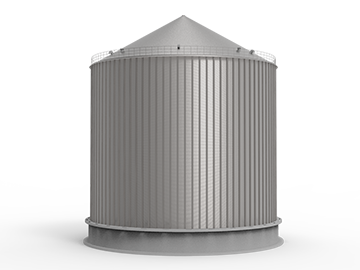

Rice Milling Production Process

Paddy

Rice

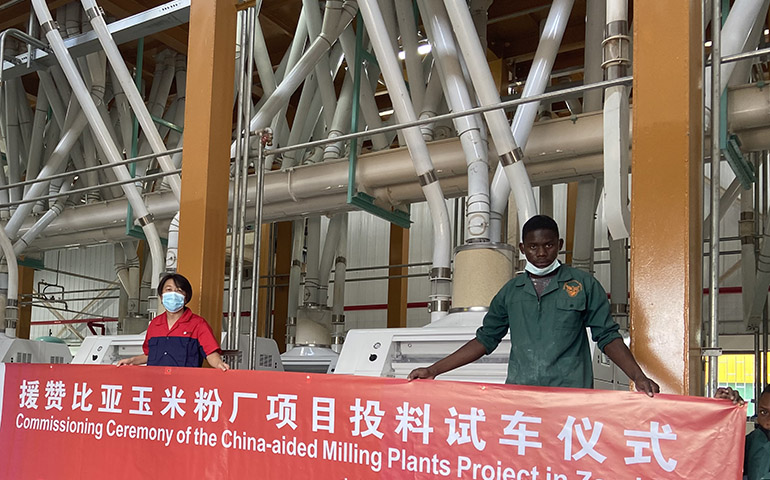

Rice Milling Projects Worldwide

You Might Also Be Interested In

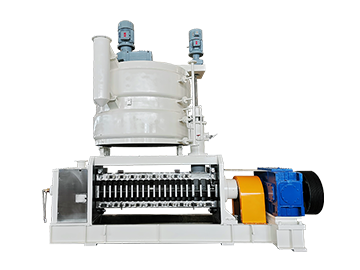

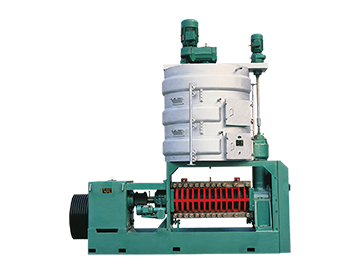

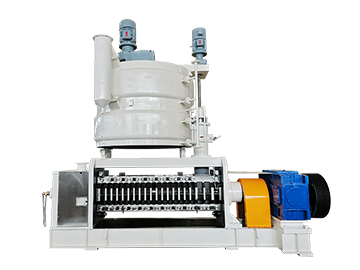

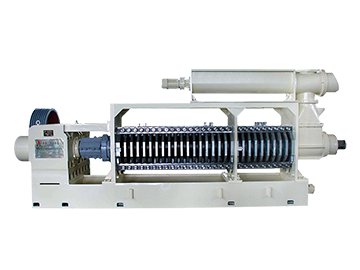

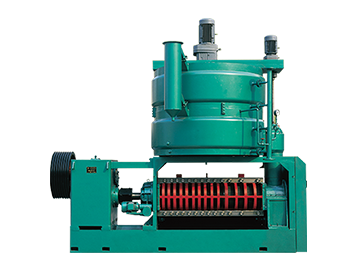

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry