Introduction of corn milling process

As a leading corn processor, COFCO Technology & Industry helps clients capitalize on the full potential of corn through customized processing solutions for food, feed and industrial applications.

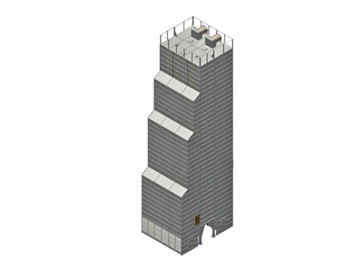

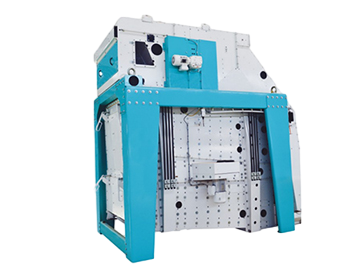

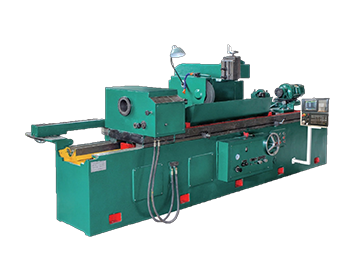

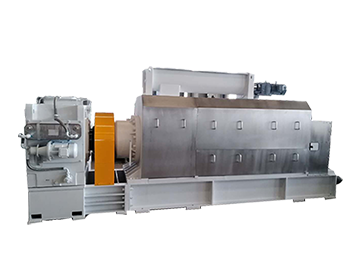

Our large-capacity automated corn processing lines incorporate the latest handling, cleaning, grading, milling, separation and extraction systems tailored to your product specifications.

Corn Milling Production Process

Corn

Corn Flour

Maize Processing Technology

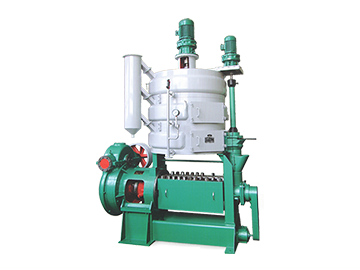

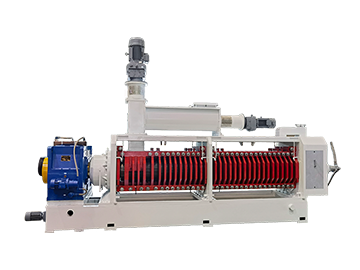

COFCO Technology & Industry specializes in delivering fully integrated, customizable maize milling solutions tailored to meet diverse industrial requirements. Our expertise spans from designing complete turnkey maize factories to providing specialized machinery for every stage of maize processing, our production processes make corn flour for tortillas, nachos, arepas, corn flour, instant maize meal and other corn based products.

Our Maize Processing Technologies Include:

Maize Meal

Hominy Grits

Extrusion Grits

Flaking Grits

Brewers Grits

Maize Germ

With cutting-edge technology and engineering excellence, we ensures that manufacturers receive end-to-end solutions designed to optimize productivity, quality, and efficiency across the entire maize milling spectrum.

Our Maize Processing Technologies Include:

Maize Meal

Hominy Grits

Extrusion Grits

Flaking Grits

Brewers Grits

Maize Germ

With cutting-edge technology and engineering excellence, we ensures that manufacturers receive end-to-end solutions designed to optimize productivity, quality, and efficiency across the entire maize milling spectrum.

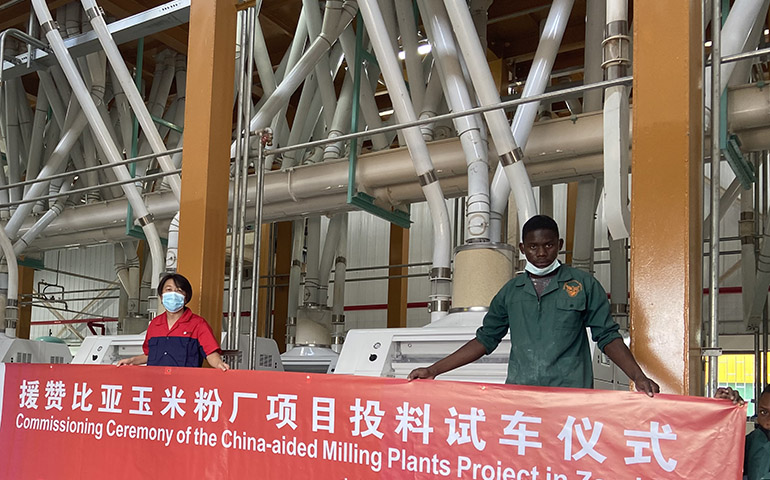

Corn Milling Projects

Maize Milling Plant Video

You Might Also Be Interested In

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry