Introduction to Seafood Cold Storage Solution

Seafood Cold Storage is mainly used for the aquatic food storage(slaughtered fish). The temperature of the seafood is below -20℃ to prevent spoilage. If it does not reach -20℃, the freshness of the seafood will be completely different.

We assist everyone, ranging from domestic food producers to global food and beverage companies.

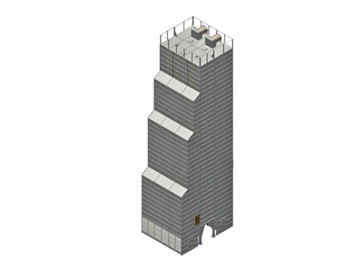

Supply Chain Solutions & Cold Storage with Integrated Technology

Generally, cold storage is cooled by refrigeration machines, using liquids with very low evaporation temperatures (ammonia or Freon) as coolants. These liquids evaporate under low pressure and mechanical control conditions, absorbing the heat inside the storage room, thereby achieving the purpose of cooling and temperature reduction.

The compression-type refrigerator is very common, which mainly consists of a compressor, condenser, throttle valve, and evaporation pipe. According to the way the evaporation pipe is installed, it can be divided into direct cooling and indirect cooling. Direct cooling installs the evaporation pipe inside the cold storage room, where the liquid coolant directly absorbs the heat inside the room through the evaporation pipe and cools down.Indirect cooling is achieved by a blower that draws the air from the storage room into an air cooling device. The air, after being cooled by the evaporation pipe inside the cooling device, is sent back into the room to reduce the temperature.

The advantage of the air cooling method is that it cools quickly, the temperature in the storage room is more uniform, and it can also remove harmful gases such as carbon dioxide produced during the storage process.

Common Temperature ranges for seafood cold storage:

-18~-25℃ freezers, which can be used for the storage of meat, aquatic products, cold drinks, and other foods.

-50~-60℃ ultra-low temperature storage, which can be used for the storage of deep-sea fish, such as tuna.

The compression-type refrigerator is very common, which mainly consists of a compressor, condenser, throttle valve, and evaporation pipe. According to the way the evaporation pipe is installed, it can be divided into direct cooling and indirect cooling. Direct cooling installs the evaporation pipe inside the cold storage room, where the liquid coolant directly absorbs the heat inside the room through the evaporation pipe and cools down.Indirect cooling is achieved by a blower that draws the air from the storage room into an air cooling device. The air, after being cooled by the evaporation pipe inside the cooling device, is sent back into the room to reduce the temperature.

The advantage of the air cooling method is that it cools quickly, the temperature in the storage room is more uniform, and it can also remove harmful gases such as carbon dioxide produced during the storage process.

Common Temperature ranges for seafood cold storage:

-18~-25℃ freezers, which can be used for the storage of meat, aquatic products, cold drinks, and other foods.

-50~-60℃ ultra-low temperature storage, which can be used for the storage of deep-sea fish, such as tuna.

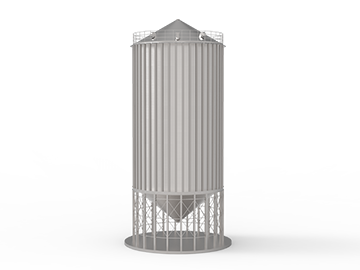

Seafood Cold Storage Projects

You Might Also Be Interested In

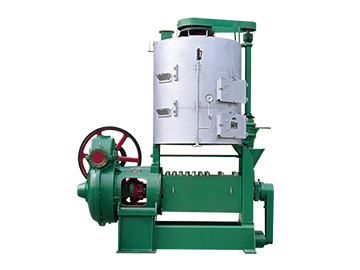

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry