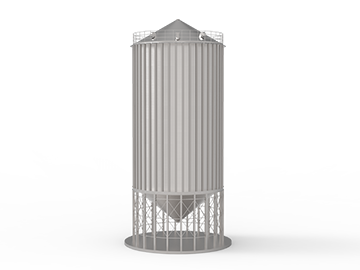

Introduction to Meat Cold Storage Solution

Meat cold storage, also known as frozen meat cold storage, is primarily used for meat, seafood, poultry, meat processing retail and wholesale industries. The products preserved in such cold storage include poultry, beef, mutton, pork, chicken, duck, goose, fish, seafood, and other meat products.

We assist everyone, ranging from domestic food producers to global food and beverage companies.

Supply Chain Solutions & Cold Storage with Integrated Technology

Cold Storage Construction Temperature:

1.The temperature of a meat cold storage is generally designed to be between -18℃ and -23℃, which is one type of low-temperature cold storage. It can preserve meat for about six months.

2.The design temperature for meat cold storage can also be 0~5℃, which is suitable for fresh meat storage of 3-10 days, especially for those that urgently require cold chain transportation.

Factors Affecting the Cost of Cold Storage Construction:

1.The size of the cold storage. The size of the cold storage is a significant factor affecting the cost of construction.

2.The temperature of the cold storage. The temperature of the cold storage is also an important factor affecting the cost of construction.

3.The selection of cold storage unit equipment.

Features of Meat Cold Storage:

1.The cold storage is chosen to be made of colored steel plates, stainless steel plates, non-toxic, tasteless, and non-rusting, which can reduce the heat generated by the temperature difference between the inside and outside, and improve the efficiency of the refrigeration system.

2.Good insulation: Meat cold storage uses composite panels made of advanced composite materials, which are lightweight, high in strength, heat-resistant, corrosion-resistant, anti-aging, pest-proof, non-toxic, mold-proof, and display their superiority under ultra-low heat preservation materials.

3.Energy-saving and low-noise refrigeration equipment.

4.The cold storage is equipped with digital display microcomputer fully automatic electrical control, automatic temperature control air conditioning, and meat cold storage does not require manual operation.

1.The temperature of a meat cold storage is generally designed to be between -18℃ and -23℃, which is one type of low-temperature cold storage. It can preserve meat for about six months.

2.The design temperature for meat cold storage can also be 0~5℃, which is suitable for fresh meat storage of 3-10 days, especially for those that urgently require cold chain transportation.

Factors Affecting the Cost of Cold Storage Construction:

1.The size of the cold storage. The size of the cold storage is a significant factor affecting the cost of construction.

2.The temperature of the cold storage. The temperature of the cold storage is also an important factor affecting the cost of construction.

3.The selection of cold storage unit equipment.

Features of Meat Cold Storage:

1.The cold storage is chosen to be made of colored steel plates, stainless steel plates, non-toxic, tasteless, and non-rusting, which can reduce the heat generated by the temperature difference between the inside and outside, and improve the efficiency of the refrigeration system.

2.Good insulation: Meat cold storage uses composite panels made of advanced composite materials, which are lightweight, high in strength, heat-resistant, corrosion-resistant, anti-aging, pest-proof, non-toxic, mold-proof, and display their superiority under ultra-low heat preservation materials.

3.Energy-saving and low-noise refrigeration equipment.

4.The cold storage is equipped with digital display microcomputer fully automatic electrical control, automatic temperature control air conditioning, and meat cold storage does not require manual operation.

Meat Cold Storage Projects

You Might Also Be Interested In

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry