Introduction of Fruit & Vegetable Cold Storage Solution

Fruit and vegetable cold storage artificially controls the composition ratio of nitrogen, oxygen, carbon dioxide, and ethylene in the gas, as well as humidity, temperature, and air pressure. By suppressing the respiration of the cells in the stored fruits, it slows down their metabolic processes, putting them in a near-dormant state. This allows for a relatively long-term preservation of the texture, color, taste, and nutrition of the stored fruits, achieving long-term freshness preservation. The temperature range for fruit and vegetable cold storage is 0℃ to 15℃.

We assist everyone, ranging from domestic food producers to global food and beverage companies.

Supply Chain Solutions & Cold Storage with Integrated Technology

Our extensive expertise encompasses every stage of the process, starting with initial design and meticulous planning, including architectural blueprints, and progressing to detailed engineering drawings required for permits. This comprehensive approach culminates in a flawless installation tailored to meet your needs seamlessly.

Features of Fruit and Vegetable Cold Storage:

1.It has a wide range of applications and is suitable for the storage and preservation of various fruits.

2.It has a long preservation period and high economic benefits. For example, grapes can be preserved for 7 months, and apples for 6 months, with the quality remaining fresh and the total loss being less than 5%.

3.The operation is simple and maintenance is convenient. The refrigeration equipment is controlled by a microcomputer to regulate the temperature, automatically turning on and off, without the need for special supervision. The supporting technology is economical and practical.

Features of Fruit and Vegetable Cold Storage:

1.It has a wide range of applications and is suitable for the storage and preservation of various fruits.

2.It has a long preservation period and high economic benefits. For example, grapes can be preserved for 7 months, and apples for 6 months, with the quality remaining fresh and the total loss being less than 5%.

3.The operation is simple and maintenance is convenient. The refrigeration equipment is controlled by a microcomputer to regulate the temperature, automatically turning on and off, without the need for special supervision. The supporting technology is economical and practical.

Fruit and Vegetable Cold Storage Projects

You Might Also Be Interested In

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

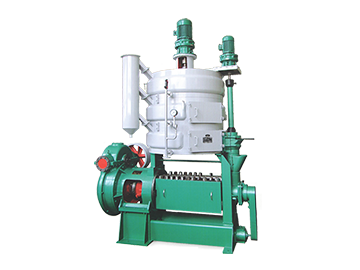

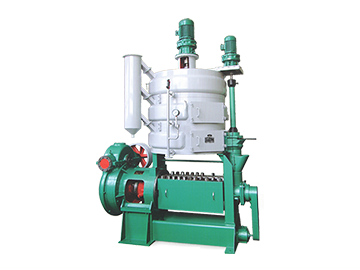

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry