Modified starch solution

Modified starch refers to starch derivatives that are produced by changing the properties of natural starch through physical, chemical, or enzymatic processes. These modifications are designed to tailor the starch properties to better meet the diverse requirements of various industries, such as food processing, pharmaceuticals, and textiles.

Modified starches can be categorized based on their origin as follows: corn modified starch, potato modified starch, tapioca modified starch, rice modified starch, wheat modified starch.

Modified starches can be categorized based on their origin as follows: corn modified starch, potato modified starch, tapioca modified starch, rice modified starch, wheat modified starch.

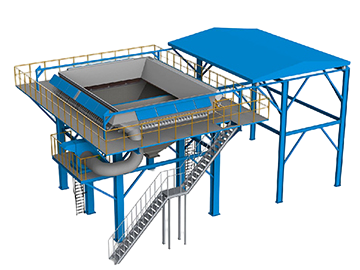

We provide a full set of services from design (process, civil, electrical), manufacturing, installation, commissioning to after-sales service; accurate 3D design, constructing 3D solid model, showing every detail of the project intuitively, accurately ; advanced automatic control system, ensuring the automatic and smooth operation of the entire production line.

Modified Starch Production Process(Enzymatic Method)

Starch

Modified Starch

Modified Starch Production Process and Applications

Production Process:

1. Dry method

Phosphate starch, acid-hydrolyzed starch, cationic starch, carboxymethyl starch

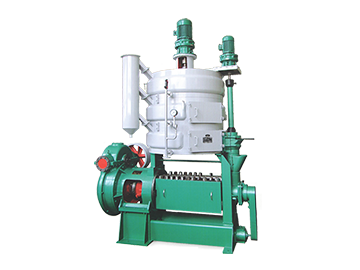

2. Wet method, organic solvent method

Carboxyl starch is generally prepared using ethanol as a solvent

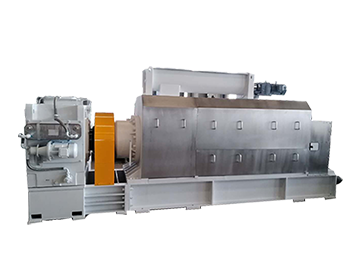

3. Extrusion method, drum drying method

Pregelatinized starch is produced using natural starch or modified starch as raw materials

Modified Starch Applications:

Pre-gelatinized starch applications:

In the food industry, it dissolves in cold water and is widely used in various convenience foods and pastries.

In animal husbandry, it is mainly used as a feed binder, with about 20-25% used in eel feed.

It can also be used as a binder in tablets, casting, and as a sizing agent in textiles.

Dextrin applications:

Primarily used as an adhesive, with stability ranking as yellow dextrin ≥ glue ≥ white dextrin.

Acid-modified starch applications:

Mainly used as a sizing agent in textiles, adhesive in papermaking, and in the production of soft candies.

Oxidized starch applications:

Used as a sizing agent in papermaking, a sizing agent in textiles, and as a food additive.

Cross-linked starch applications:

Used as a thickener in food (suitable for canned and frozen foods), as an anti-adherent in medical applications (lubricant for surgical gloves), for electrolyte concentration in batteries, and to produce complex modified starches by reacting with other chemicals.

Hydroxyalkyl starch applications:

Mainly used in textiles, papermaking, or as dextran in the pharmaceutical industry.

Cationic starch applications:

A good emulsifier and flocculant, used in textiles, papermaking, oil drilling, and industrial wastewater treatment.

Carboxymethyl starch (CMS) applications:

Used as a thickener, suspending agent, stabilizer, and binder in the food industry, as a binder and disintegrant in pharmaceuticals, and in cosmetics, textiles, and papermaking.

Esterified starch applications:

Acetylated starch can be used in textiles, papermaking, and starch film production. Xanthate esterified starch can remove heavy metals and pesticides embedded in acidic wastewater. Phosphate esterified starch can be used as a thickener, stabilizer, and emulsifier in the food industry, and also in textiles and papermaking.

Graft copolymer starch applications:

Mainly used as an absorbent, such as in facial tissues, diapers, and toilet paper, as well as in agriculture, forestry, and horticulture.

1. Dry method

Phosphate starch, acid-hydrolyzed starch, cationic starch, carboxymethyl starch

2. Wet method, organic solvent method

Carboxyl starch is generally prepared using ethanol as a solvent

3. Extrusion method, drum drying method

Pregelatinized starch is produced using natural starch or modified starch as raw materials

Modified Starch Applications:

Pre-gelatinized starch applications:

In the food industry, it dissolves in cold water and is widely used in various convenience foods and pastries.

In animal husbandry, it is mainly used as a feed binder, with about 20-25% used in eel feed.

It can also be used as a binder in tablets, casting, and as a sizing agent in textiles.

Dextrin applications:

Primarily used as an adhesive, with stability ranking as yellow dextrin ≥ glue ≥ white dextrin.

Acid-modified starch applications:

Mainly used as a sizing agent in textiles, adhesive in papermaking, and in the production of soft candies.

Oxidized starch applications:

Used as a sizing agent in papermaking, a sizing agent in textiles, and as a food additive.

Cross-linked starch applications:

Used as a thickener in food (suitable for canned and frozen foods), as an anti-adherent in medical applications (lubricant for surgical gloves), for electrolyte concentration in batteries, and to produce complex modified starches by reacting with other chemicals.

Hydroxyalkyl starch applications:

Mainly used in textiles, papermaking, or as dextran in the pharmaceutical industry.

Cationic starch applications:

A good emulsifier and flocculant, used in textiles, papermaking, oil drilling, and industrial wastewater treatment.

Carboxymethyl starch (CMS) applications:

Used as a thickener, suspending agent, stabilizer, and binder in the food industry, as a binder and disintegrant in pharmaceuticals, and in cosmetics, textiles, and papermaking.

Esterified starch applications:

Acetylated starch can be used in textiles, papermaking, and starch film production. Xanthate esterified starch can remove heavy metals and pesticides embedded in acidic wastewater. Phosphate esterified starch can be used as a thickener, stabilizer, and emulsifier in the food industry, and also in textiles and papermaking.

Graft copolymer starch applications:

Mainly used as an absorbent, such as in facial tissues, diapers, and toilet paper, as well as in agriculture, forestry, and horticulture.

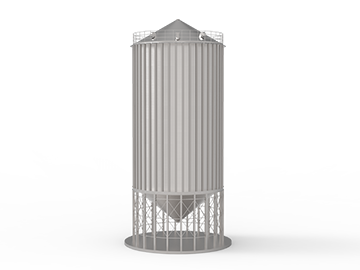

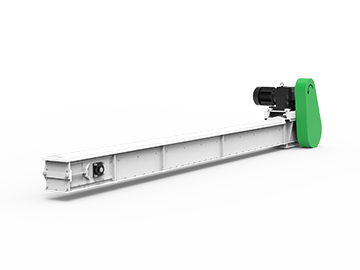

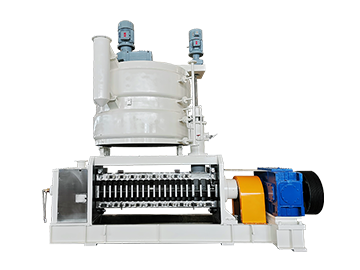

Modified Satrch Projects

You Might Also Be Interested In

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry