Corn Starch Solution

Corn starch is a fine, odorless, flavorless white powder derived from the endosperm of the corn kernel.

Corn starch can be consumed directly as human food as well as an important raw material for producing starch sugar. It is widely used in pharmaceutical, textile, fermentation, chemical and other industries.

We boast over 30 years of corn starch industry experience and technical acumen, backed by a team of professional experts. We offer our clients comprehensive services, including process design, custom equipment design, 3D modeling, automation and electrical engineering, installation and commissioning, as well as training and after-sales support.

Corn Starch Production Process

Corn

Corn Starch

Corn Starch Processing Technology

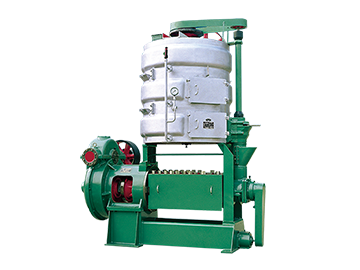

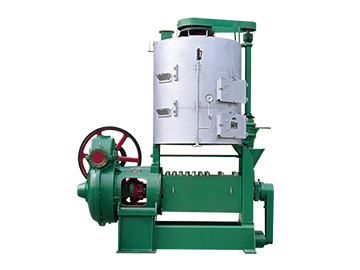

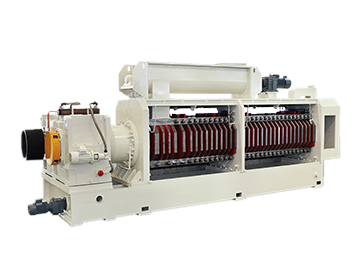

The production process of corn starch adopts the world's advanced wet grinding closed-circuit production process. China's advanced equipment with reliable operation, high efficiency and energy saving is adopted to make the comprehensive indicators of corn processing, including the yield, quality and energy consumption of main and by-products, reach the world advanced level.

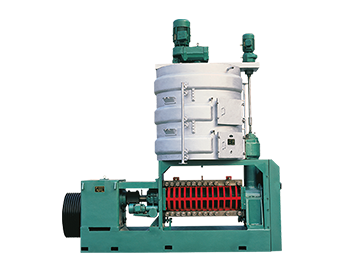

The corn starch production line designed by our company uses live steam in addition to the starch drying system and tube bundle dryer system. Other systems such as corn conveying water heating, soaking liquid circulation heating, new acid heating, corn pulp evaporation, etc. all use waste heat; the exhaust gas of all equipment in the workshop is collected and uniformly recycled into the efficient absorption tower, and then discharged after treatment meets the standards.

Corn deep processing products

1. Starch and by-product workshop

Corn

Gluten

Fiber/corn pulp/germ

2. Starch sweetener workshop

Maltose

Glucose

Sugar alcohol (sorbitol, mannitol, etc.)

3. Fermentation product workshop

Citric acid

Lysine

The corn starch production line designed by our company uses live steam in addition to the starch drying system and tube bundle dryer system. Other systems such as corn conveying water heating, soaking liquid circulation heating, new acid heating, corn pulp evaporation, etc. all use waste heat; the exhaust gas of all equipment in the workshop is collected and uniformly recycled into the efficient absorption tower, and then discharged after treatment meets the standards.

Corn deep processing products

1. Starch and by-product workshop

Corn

Gluten

Fiber/corn pulp/germ

2. Starch sweetener workshop

Maltose

Glucose

Sugar alcohol (sorbitol, mannitol, etc.)

3. Fermentation product workshop

Citric acid

Lysine

Corn starch projects

You Might Also Be Interested In

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry