Fructose Syrup Production Solution

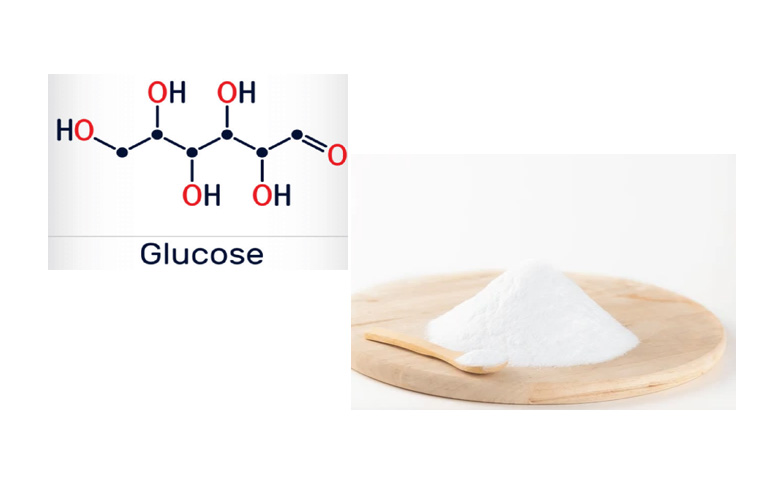

High Fructose Syrup (HFS), also known as isomerized syrup, is a type of starch sugar made from corn or wheat starch. Its production process involves two main steps: first, starch is hydrolyzed into glucose using enzymatic methods; then, glucose isomerase catalyzes the conversion of part of the glucose into fructose, resulting in a mixed syrup composed of fructose and glucose.

We provide a full set of services from design (process, civil, electrical), manufacturing, installation, commissioning to after-sales service; accurate 3D design, constructing 3D solid model, showing every detail of the project intuitively, accurately ; advanced automatic control system, ensuring the automatic and smooth operation of the entire production line.

Process Description

Starch

Fructose syrup

Our Technical Advantages

We provide one-stop services from conceptual design to construction drawing design.

We have professional technical teams in process engineering, electrical automation, equipment, architecture, structural engineering, water supply and drainage, and HVAC, enabling high-quality, efficient, and comprehensive engineering services.

Key technical personnel at COFCO Technoloy & Industry come from the production frontlines of well-known enterprises in the same industry, with deep familiarity with process flows. Their firsthand production experience is integrated into the design process, facilitating successful project commissioning on the first attempt.

With years of experience in starch sugar design, COFCO Technology & Industry can tailor process solutions to client needs, utilizing technologies such as heat recovery and waste liquid recycling to provide cost-effective operational schemes.

We have professional technical teams in process engineering, electrical automation, equipment, architecture, structural engineering, water supply and drainage, and HVAC, enabling high-quality, efficient, and comprehensive engineering services.

Key technical personnel at COFCO Technoloy & Industry come from the production frontlines of well-known enterprises in the same industry, with deep familiarity with process flows. Their firsthand production experience is integrated into the design process, facilitating successful project commissioning on the first attempt.

With years of experience in starch sugar design, COFCO Technology & Industry can tailor process solutions to client needs, utilizing technologies such as heat recovery and waste liquid recycling to provide cost-effective operational schemes.

Starch & Derivatives Projects

You Might Also Be Interested In

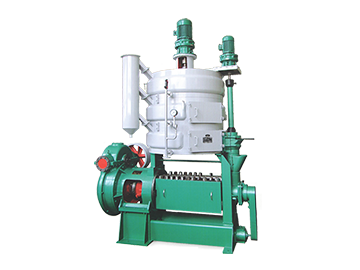

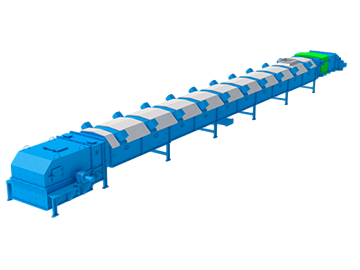

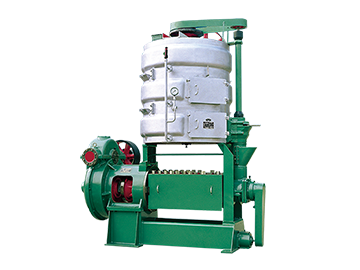

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry