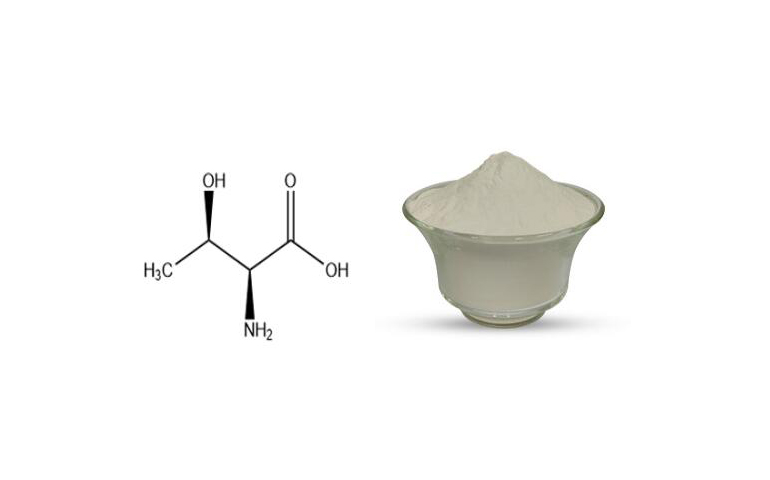

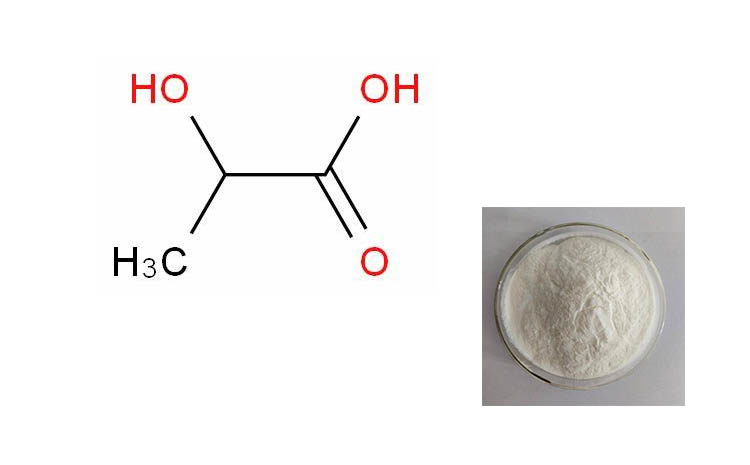

Introduction of Lactic Acid

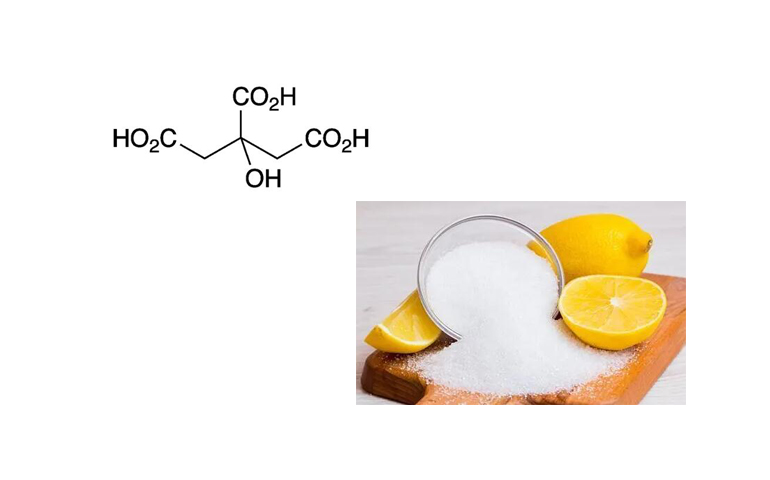

Lactic acid is one of the most useful substances for the beverage industry as a preservative, and in the chemical industry as a raw material for the production of lactate ester, propylene glycol, 2,3-pentanedione, propionic acid, acrylic acid, acetaldehyde, and dilactide.

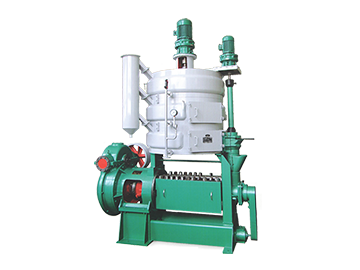

We provide a full range of engineering services, including project preparatory work, overall design, equipment supply, electrical automation, installation guidance and commissioning.

Lactic Acid Production Process(biological fermentation)

Grain

Lactic Acid

Lactic Acid Production Technology

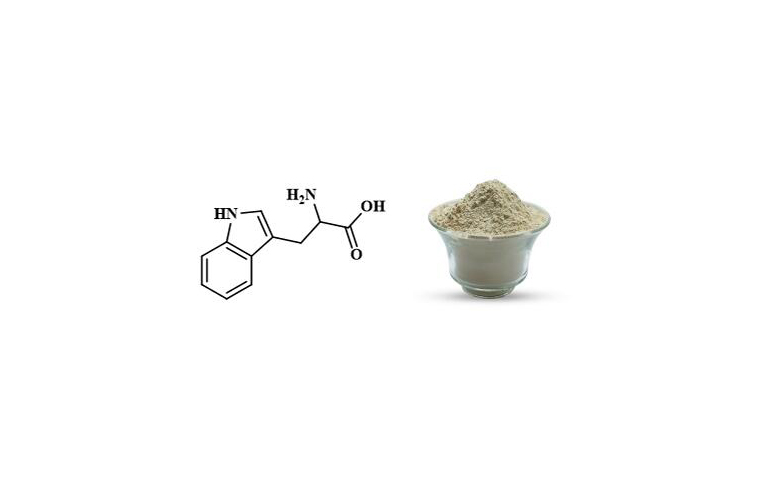

Lactic acid is a new product that uses starchy grains (such as corn, rice, and potato chips) as raw materials and produces organic acids through biological fermentation, thereby increasing the added value of grains.

The process for producing and purifying lactic acid begins with the cultivation of microorganisms that generate lactate on a cost-effective substrate composed of carbohydrates, corn steep liquor, and corn oil, until the carbohydrates are predominantly converted to lactic acid. Subsequently, the fermentation broth undergoes electrodialysis to recover and concentrate the lactate present in the aqueous solution, which is derived from the hydrolysis of the electrodialysis process that yields alkali and lactic acid products. The lactic acid product is then refined by first passing it through a strong acid cation exchanger in its acid form to eliminate all sodium ions and other cations. This is followed by treatment with a weak base anion exchanger in its free base form to remove sulfate ions or sulfate, culminating in the achievement of a highly purified lactic acid product.

Latic acid application:

In the food industry, lactic acid is used for preservation and freshness, pH adjustment, antibacterial effects, and flavor enhancement. It is an important ingredient in the production of candies, beverages, bread, and other foods.

In the pharmaceutical industry, lactic acid is used for disinfection, making pharmaceutical preparations and health products.

Additionally, lactic acid is applied in various industries such as agriculture, textiles, coatings, and plastics.

The process for producing and purifying lactic acid begins with the cultivation of microorganisms that generate lactate on a cost-effective substrate composed of carbohydrates, corn steep liquor, and corn oil, until the carbohydrates are predominantly converted to lactic acid. Subsequently, the fermentation broth undergoes electrodialysis to recover and concentrate the lactate present in the aqueous solution, which is derived from the hydrolysis of the electrodialysis process that yields alkali and lactic acid products. The lactic acid product is then refined by first passing it through a strong acid cation exchanger in its acid form to eliminate all sodium ions and other cations. This is followed by treatment with a weak base anion exchanger in its free base form to remove sulfate ions or sulfate, culminating in the achievement of a highly purified lactic acid product.

Latic acid application:

In the food industry, lactic acid is used for preservation and freshness, pH adjustment, antibacterial effects, and flavor enhancement. It is an important ingredient in the production of candies, beverages, bread, and other foods.

In the pharmaceutical industry, lactic acid is used for disinfection, making pharmaceutical preparations and health products.

Additionally, lactic acid is applied in various industries such as agriculture, textiles, coatings, and plastics.

Latic Acid Projects

You Might Also Be Interested In

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry