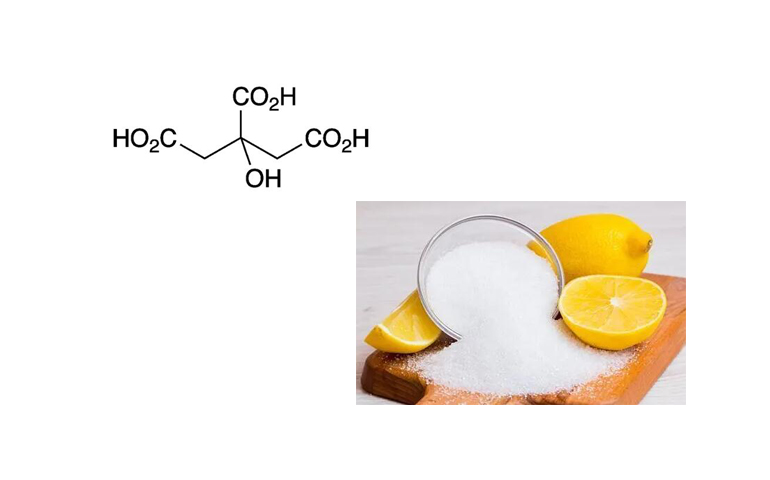

Introduction of Citric Acid

Citric acid is an important organic acid that is soluble in water and is a natural preservative and food additive. According to the difference of its water content, it can be divided into citric acid monohydrate and anhydrous citric acid. It is the most important organic acid widely used in food, pharmaceutical, daily chemical and other industries due to its physical properties, chemical properties and derivative properties.

We provide a full range of engineering services, including project preparatory work, overall design, equipment supply, electrical automation, installation guidance and commissioning.

Citric Acid Production Process(raw material: corn)

Corn

Citric Acid

COFCO Technology & Industry Technical Advantages

I.Fermentation Technology

COFCO Technology & Industry employs high-efficiency microbial fermentation technology, utilizing superior strains such as Aspergillus niger as the core to achieve high-yield, low-cost citric acid production. Through directed strain improvement using genetic engineering and metabolic engineering techniques, fermentation efficiency and product yield are significantly enhanced, maintaining a continuous technological leadership position in the industry.

II.Process Technology

COFCO Technology & Industry has innovatively developed the calcium hydrogen citrate extraction process and successfully implemented it on a large-scale industrial level. This process offers the following advantages:

Significantly reduces acid and alkali consumption, lowering production costs;

Effectively treats high-concentration organic wastewater, reducing pollutant emissions;

Achieves green production by reducing environmental impact through clean production technologies.

COFCO Technology & Industry employs high-efficiency microbial fermentation technology, utilizing superior strains such as Aspergillus niger as the core to achieve high-yield, low-cost citric acid production. Through directed strain improvement using genetic engineering and metabolic engineering techniques, fermentation efficiency and product yield are significantly enhanced, maintaining a continuous technological leadership position in the industry.

II.Process Technology

COFCO Technology & Industry has innovatively developed the calcium hydrogen citrate extraction process and successfully implemented it on a large-scale industrial level. This process offers the following advantages:

Significantly reduces acid and alkali consumption, lowering production costs;

Effectively treats high-concentration organic wastewater, reducing pollutant emissions;

Achieves green production by reducing environmental impact through clean production technologies.

Organic Acid Projects

You Might Also Be Interested In

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry