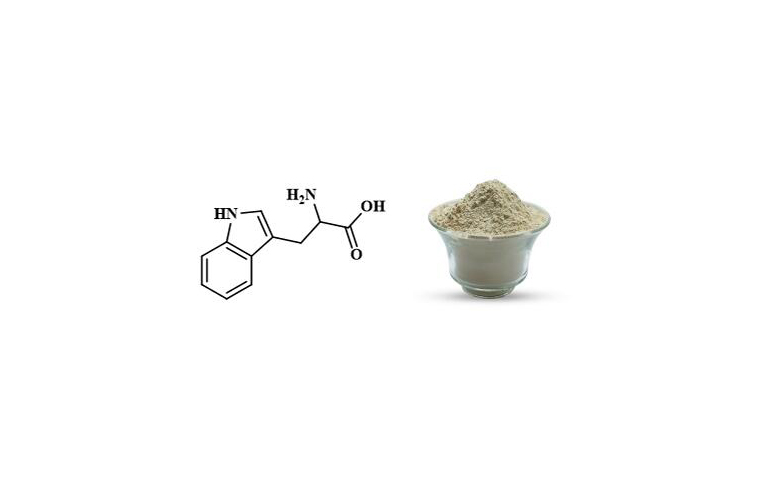

Introduction of Tryptophan Solution

Tryptophan is an essential amino acid for mammals, existing as white to yellowish-white crystals or crystalline powder. L-Tryptophan is a crucial component in the formation of body proteins, participating in the regulation of protein synthesis and fat metabolism. It also has a very close relationship with the metabolic regulation of other substances, such as carbohydrates, vitamins, and trace elements. Tryptophan can be produced through microbial fermentation using glucose derived from the saccharification of starch milk (from grains like corn, wheat, and rice) as a carbon source, typically by microorganisms such as Escherichia coli, Corynebacterium glutamicum, and Brevibacterium flavum.

We provide a full range of engineering services, including project preparatory work, overall design, equipment supply, electrical automation, installation guidance and commissioning.

Tryptophan Production Process

Starch

Tryptophan

Application Fields of Tryptophan

Feed Industry

Tryptophan promotes the feeding of animals, reduces stress reactions, improves animal sleep, and can also increase antibodies in fetuses and young animals, and improve the lactation of dairy animals. It reduces the use of high-quality protein in the daily diet, saving feed costs, and reduces the use of protein feed in the diet, saving formulation space, etc.

Food Industry

Tryptophan can be used as a nutritional supplement, food fortifier, or preservative, in the production of nutritional supplements for women and children, such as milk powder, fermentation of bread and other baked goods, or preservation of fish and meat products. In addition, tryptophan can also serve as a biosynthetic precursor for the fermentation production of the food color indigotin, to increase the production of indigo.

Pharmaceutical Industry

Tryptophan is commonly used in the fields of health products, bio-pharmaceuticals, and pharmaceutical raw materials. Tryptophan can enhance immunity and is used in the synthesis of drugs for the treatment of schizophrenia and sedative-antidepressant medications. Tryptophan can be used directly in clinical settings as a drug, or as a precursor in the production of some drugs, such as prodigiosin.

Tryptophan promotes the feeding of animals, reduces stress reactions, improves animal sleep, and can also increase antibodies in fetuses and young animals, and improve the lactation of dairy animals. It reduces the use of high-quality protein in the daily diet, saving feed costs, and reduces the use of protein feed in the diet, saving formulation space, etc.

Food Industry

Tryptophan can be used as a nutritional supplement, food fortifier, or preservative, in the production of nutritional supplements for women and children, such as milk powder, fermentation of bread and other baked goods, or preservation of fish and meat products. In addition, tryptophan can also serve as a biosynthetic precursor for the fermentation production of the food color indigotin, to increase the production of indigo.

Pharmaceutical Industry

Tryptophan is commonly used in the fields of health products, bio-pharmaceuticals, and pharmaceutical raw materials. Tryptophan can enhance immunity and is used in the synthesis of drugs for the treatment of schizophrenia and sedative-antidepressant medications. Tryptophan can be used directly in clinical settings as a drug, or as a precursor in the production of some drugs, such as prodigiosin.

Lysine Production Projects

You Might Also Be Interested In

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry