Tryptophan Production Solution

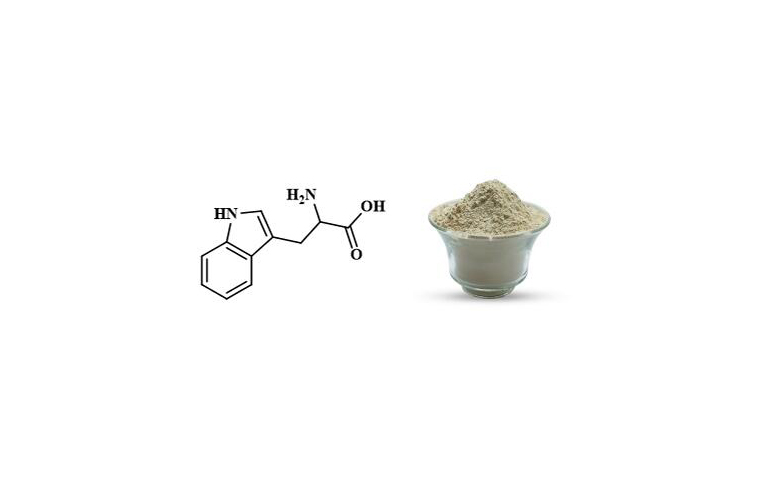

Tryptophan (Trp) is an important essential amino acid that the human body cannot synthesize on its own and must be obtained through diet or external supplementation. It is a critical component in protein synthesis and serves as a precursor to various bioactive substances (such as serotonin and melatonin), playing a vital role in neurological regulation, immune function, and metabolic balance. The production of tryptophan primarily involves three technical approaches: microbial fermentation, chemical synthesis, and enzymatic catalysis. Among these, the predominant method is microbial fermentation.

We provide a full range of engineering services, including project preparatory work, overall design, equipment supply, electrical automation, installation guidance and commissioning.

Process Flow of Microbial Fermentation Method

Starch

Tryptophan

Tryptophan: Product Forms and Core Functions

Main Product Forms of Tryptophan

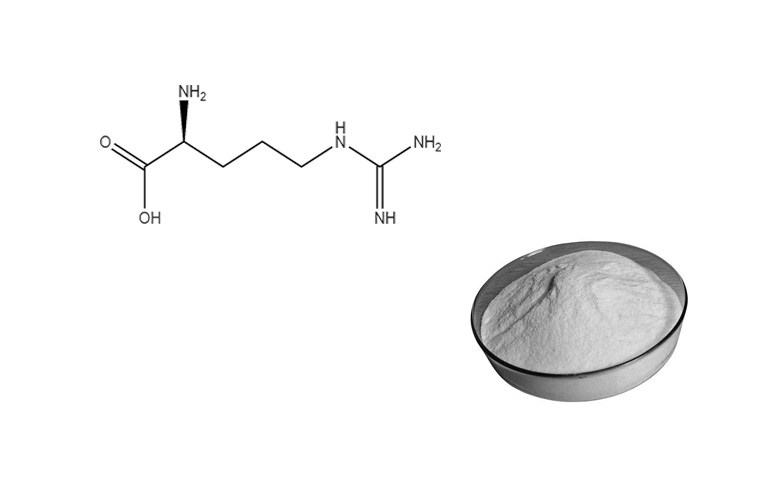

1. L-Tryptophan

The naturally occurring bioactive form, widely used in pharmaceuticals, food, and feed additives.

Common dosage forms: powder, capsules, tablets.

2. Tryptophan Derivatives

5-Hydroxytryptophan (5-HTP): A direct precursor for serotonin synthesis, used for anti-depression and sleep improvement.

Melatonin: Produced through tryptophan metabolism, regulates the sleep-wake cycle.

3. Industrial-Grade Tryptophan

Used in animal feed (e.g., for pigs and poultry) to promote growth and reduce stress.

Core Functions

1. Neurological Regulation and Mental Health

Synthesizes serotonin ("happiness hormone") to improve depression, anxiety, and mood disorders.

Converts to melatonin to regulate sleep patterns and alleviate insomnia.

2. Protein Synthesis and Metabolism

As an essential amino acid, it participates in the body’s protein construction, promoting muscle growth and repair.

3. Immune Regulation

Supports immune cell function and reduces inflammatory responses.

4. Animal Nutrition

When added to feed, it reduces stress-related behaviors in animals (e.g., tail-biting in pigs) and improves feed efficiency.

1. L-Tryptophan

The naturally occurring bioactive form, widely used in pharmaceuticals, food, and feed additives.

Common dosage forms: powder, capsules, tablets.

2. Tryptophan Derivatives

5-Hydroxytryptophan (5-HTP): A direct precursor for serotonin synthesis, used for anti-depression and sleep improvement.

Melatonin: Produced through tryptophan metabolism, regulates the sleep-wake cycle.

3. Industrial-Grade Tryptophan

Used in animal feed (e.g., for pigs and poultry) to promote growth and reduce stress.

Core Functions

1. Neurological Regulation and Mental Health

Synthesizes serotonin ("happiness hormone") to improve depression, anxiety, and mood disorders.

Converts to melatonin to regulate sleep patterns and alleviate insomnia.

2. Protein Synthesis and Metabolism

As an essential amino acid, it participates in the body’s protein construction, promoting muscle growth and repair.

3. Immune Regulation

Supports immune cell function and reduces inflammatory responses.

4. Animal Nutrition

When added to feed, it reduces stress-related behaviors in animals (e.g., tail-biting in pigs) and improves feed efficiency.

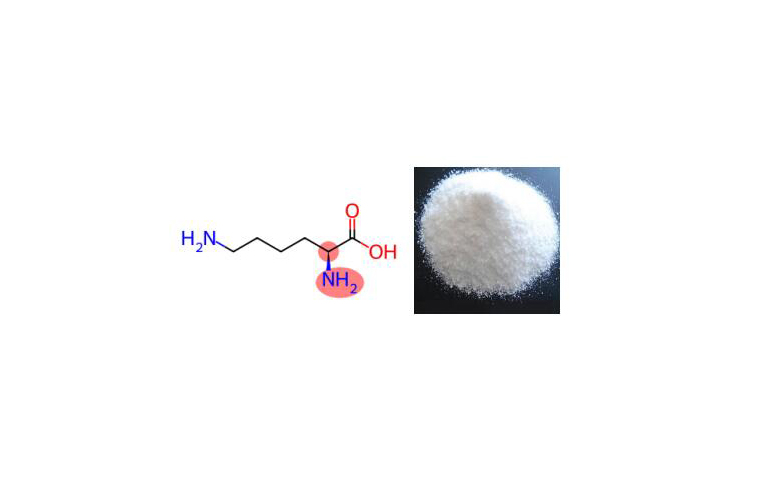

Lysine Production Projects

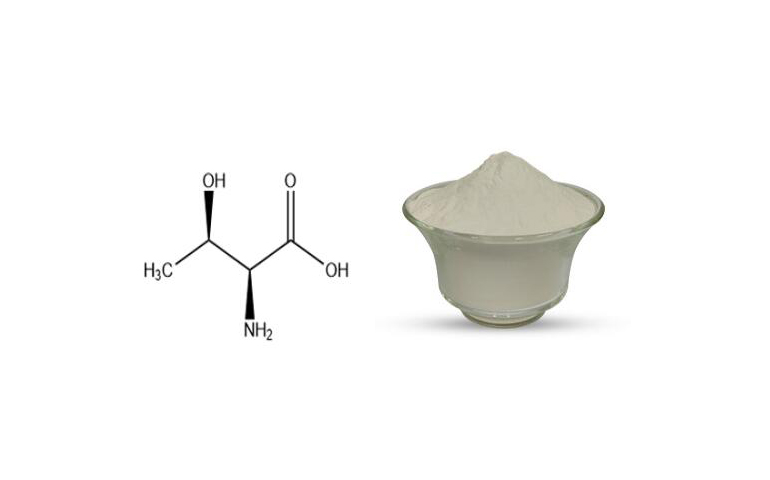

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry