Lysine Production Solution

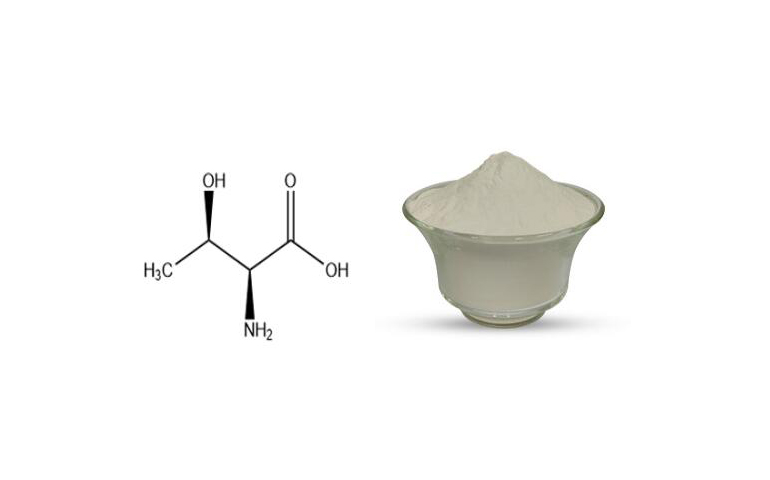

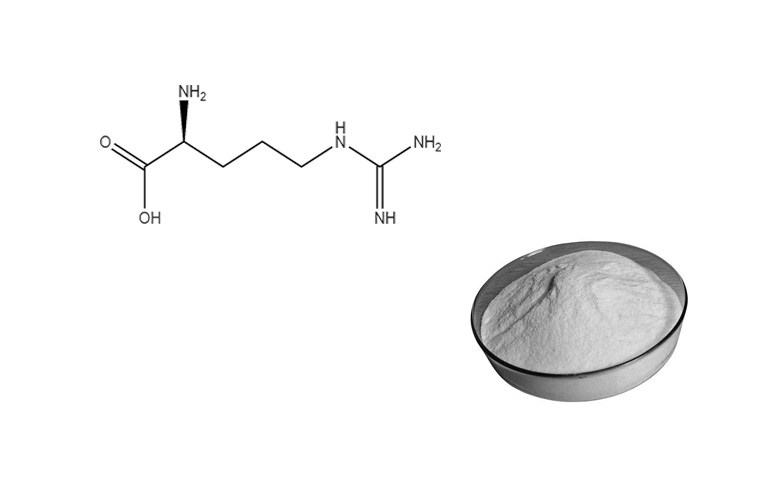

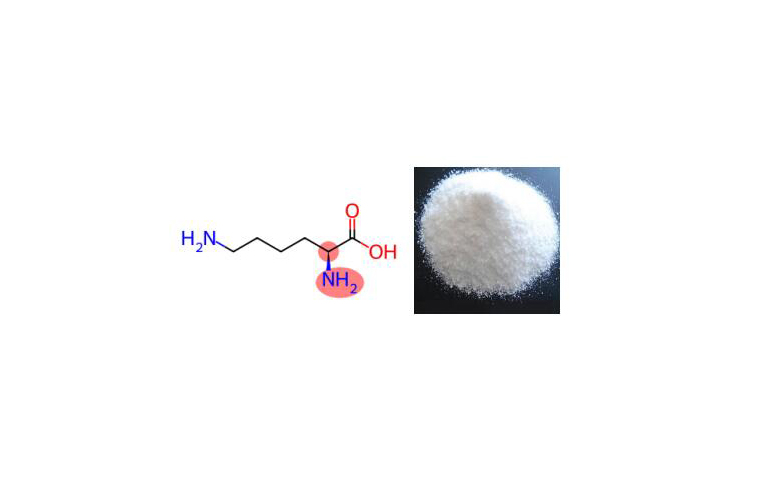

Lysine is an essential basic amino acid that the human body cannot synthesize and must obtain from the diet. It finds extensive applications in the food, pharmaceutical, and feed industries. Industrially, lysine is produced through microbial fermentation, primarily utilizing starchy raw materials like wheat as the chief carbon source. The production process encompasses several stages, including pretreatment, fermentation, extraction, and purification.

We provide a full range of engineering services, including project preparatory work, overall design, equipment supply, electrical automation, installation guidance and commissioning.

Lysine Production Process

Grain

Lysine

COFCO Technology & Industry Technical Advantages

Strain Innovation and Engineering Integration Capabilities

Through metabolic engineering techniques, random mutation and screening of strains have been conducted, successfully developing recombinant high-yield strains that significantly enhance lysine production.

Engineering Design and EPC (Engineering, Procurement, and Construction) Advantage: Leveraging COFCO Technology & Industry's expertise in engineering design, we achieve full-chain coverage from strain development to electromechanical EPC, maintaining a leading position in the field of amino acid fermentation in China.

Policy Orientation and Market Expansion

Serving National Strategies: Our technological achievements directly support the national "Belt and Road" development strategy, facilitating the expansion of amino acid deep-processing businesses in overseas markets (e.g., Southeast Asia and the Middle East).

Diverse Application Scenarios: Our products cater to the feed, pharmaceutical, and food industries, meeting customized demands for lysine purity (e.g., pharmaceutical grade ≥99.5%) and functionality across different clients.

Technical Collaboration and Resource Integration

Industry-Academia-Research Collaboration: Long-term partnerships with institutions like Jiangnan University have been established to jointly advance strain modification and process optimization, accelerating technological iteration and achievement transformation.

Circular Economy Model: Byproducts such as fermentation waste liquid are repurposed to produce bacterial cellulose or compound fertilizers, achieving a resource utilization rate of 92%, aligning with green manufacturing trends.

Through metabolic engineering techniques, random mutation and screening of strains have been conducted, successfully developing recombinant high-yield strains that significantly enhance lysine production.

Engineering Design and EPC (Engineering, Procurement, and Construction) Advantage: Leveraging COFCO Technology & Industry's expertise in engineering design, we achieve full-chain coverage from strain development to electromechanical EPC, maintaining a leading position in the field of amino acid fermentation in China.

Policy Orientation and Market Expansion

Serving National Strategies: Our technological achievements directly support the national "Belt and Road" development strategy, facilitating the expansion of amino acid deep-processing businesses in overseas markets (e.g., Southeast Asia and the Middle East).

Diverse Application Scenarios: Our products cater to the feed, pharmaceutical, and food industries, meeting customized demands for lysine purity (e.g., pharmaceutical grade ≥99.5%) and functionality across different clients.

Technical Collaboration and Resource Integration

Industry-Academia-Research Collaboration: Long-term partnerships with institutions like Jiangnan University have been established to jointly advance strain modification and process optimization, accelerating technological iteration and achievement transformation.

Circular Economy Model: Byproducts such as fermentation waste liquid are repurposed to produce bacterial cellulose or compound fertilizers, achieving a resource utilization rate of 92%, aligning with green manufacturing trends.

Lysine Production Project

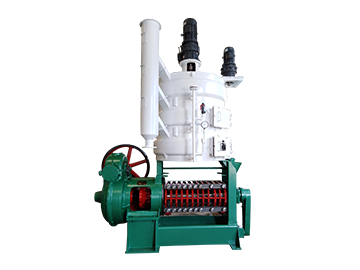

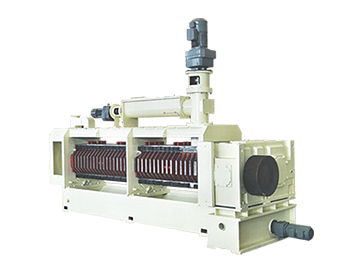

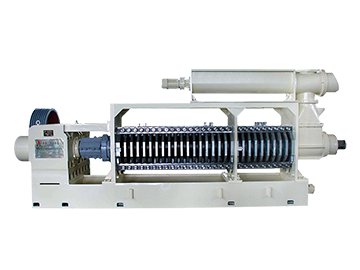

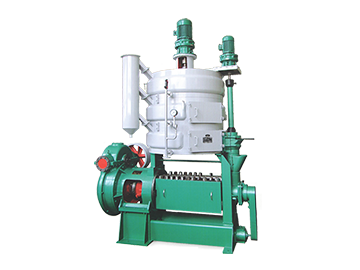

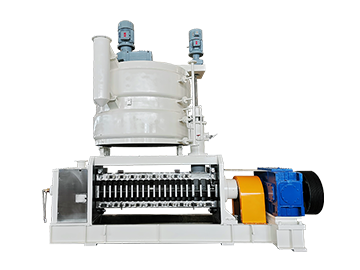

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry