I

n

t

r

o

d

u

c

t

i

o

n

o

f

L

-

L

y

s

i

n

e

S

o

l

u

t

i

o

n

L

-

L

y

s

i

n

e

P

r

o

d

u

c

t

i

o

n

P

r

o

c

e

s

s

Grain

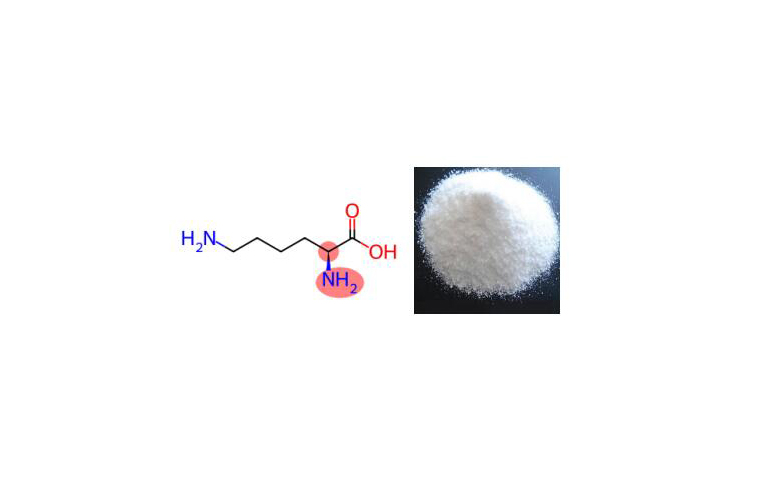

L-Lysine

A

p

p

l

i

c

a

t

i

o

n

F

i

e

l

d

s

o

f

L

-

L

y

s

i

n

e

Feed Industry

Adding an appropriate proportion of lysine to feed can improve the balance of amino acids in the feed, increase feed utilization, and promote the growth of animals and the improvement of meat quality.

Food Industry

Due to the low content of lysine in grains and its destruction during processing, leading to a deficiency, lysine is the first limiting amino acid. Adding it to food can promote growth and development, increase appetite, reduce the incidence of diseases, and strengthen the body. It also has anti-odour and preservative effects when used in canned food.

Pharmaceutical Industry

Lysine can be used to prepare compound amino acid infusions, which have better effects and fewer side effects than hydrolyzed protein infusions. Lysine can be combined with various vitamins and glucose to produce nutritional supplements that are easily absorbed by the gastrointestinal tract after oral intake. Lysine can also improve the performance of certain drugs and enhance their efficacy.

Adding an appropriate proportion of lysine to feed can improve the balance of amino acids in the feed, increase feed utilization, and promote the growth of animals and the improvement of meat quality.

Food Industry

Due to the low content of lysine in grains and its destruction during processing, leading to a deficiency, lysine is the first limiting amino acid. Adding it to food can promote growth and development, increase appetite, reduce the incidence of diseases, and strengthen the body. It also has anti-odour and preservative effects when used in canned food.

Pharmaceutical Industry

Lysine can be used to prepare compound amino acid infusions, which have better effects and fewer side effects than hydrolyzed protein infusions. Lysine can be combined with various vitamins and glucose to produce nutritional supplements that are easily absorbed by the gastrointestinal tract after oral intake. Lysine can also improve the performance of certain drugs and enhance their efficacy.

L

y

s

i

n

e

P

r

o

d

u

c

t

i

o

n

P

r

o

j

e

c

t

Y

o

u

M

i

g

h

t

A

l

s

o

B

e

I

n

t

e

r

e

s

t

e

d

I

n

R

e

l

a

t

e

d

P

r

o

d

u

c

t

s

Y

o

u

A

r

e

W

e

l

c

o

m

e

T

o

C

o

n

s

u

l

t

O

u

r

S

o

l

u

t

i

o

n

s

,

W

e

W

i

l

l

C

o

m

m

u

n

i

c

a

t

e

W

i

t

h

Y

o

u

I

n

T

i

m

e

A

n

d

P

r

o

v

i

d

e

P

r

o

f

e

s

s

i

o

n

a

l

S

o

l

u

t

i

o

n

s

F

u

l

l

L

i

f

e

c

y

c

l

e

S

e

r

v

i

c

e

W

e

'

r

e

H

e

r

e

t

o

H

e

l

p

.

F

r

e

q

u

e

n

t

l

y

A

s

k

e

d

Q

u

e

s

t

i

o

n

s

I

n

q

u

i

r

y