Introduction of Glutamic Acid Solution

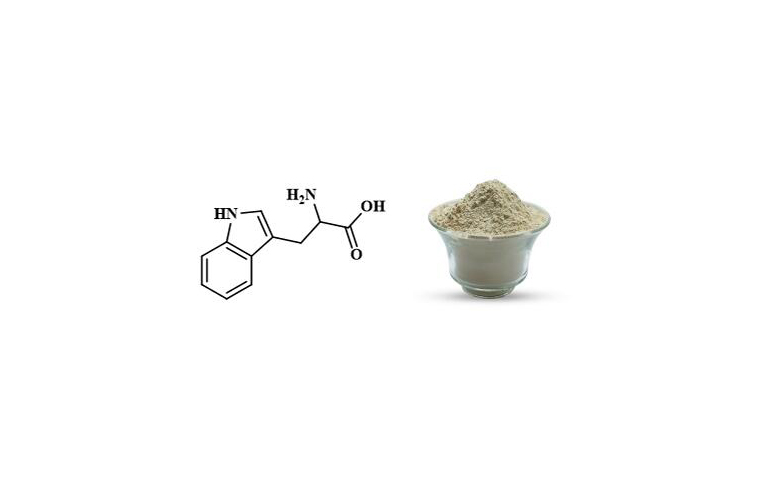

Glutamic Acid is an important non-essential amino acid widely found in nature and one of the primary components of proteins. Its sodium salt form, sodium glutamate (MSG, monosodium glutamate), is the most common food additive. Glutamic acid and its derivatives have extensive applications in pharmaceuticals, food, cosmetics, and agriculture.

The biological fermentation production of glutamic acid utilizes starchy raw materials (such as corn and cassava) as the primary carbon source, achieving industrial-scale production through four main stages: pretreatment, fermentation, extraction, and purification.

The biological fermentation production of glutamic acid utilizes starchy raw materials (such as corn and cassava) as the primary carbon source, achieving industrial-scale production through four main stages: pretreatment, fermentation, extraction, and purification.

We provide a full range of engineering services, including project preparatory work, overall design, equipment supply, electrical automation, installation guidance and commissioning.

Biological Fermentation Process Flow

Corn

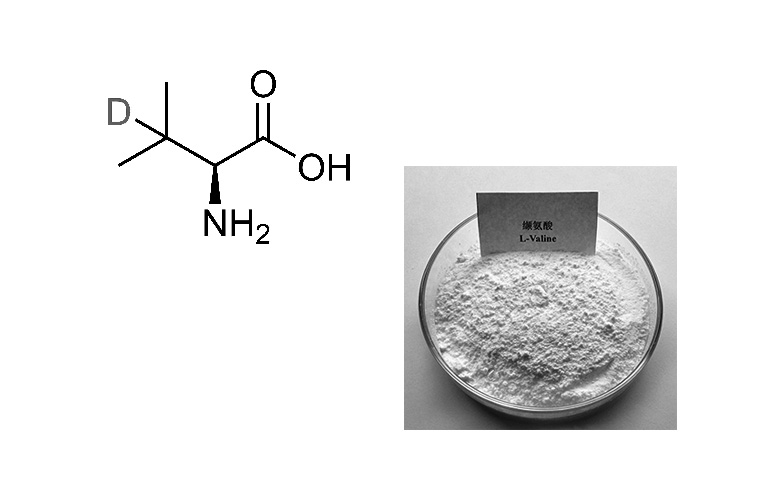

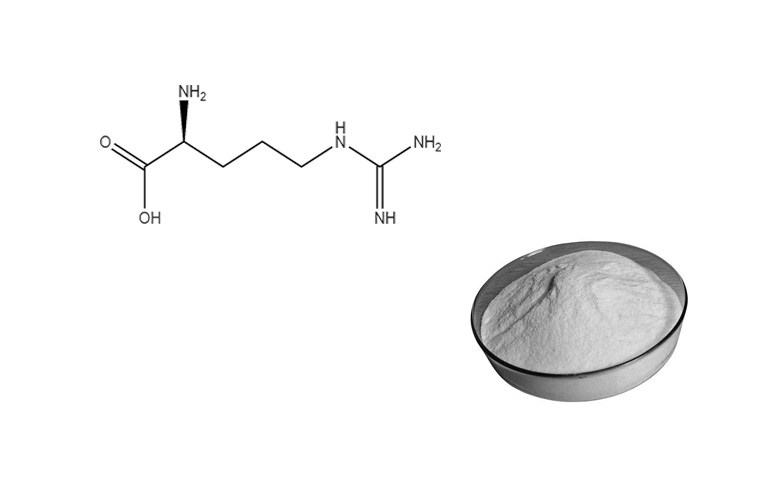

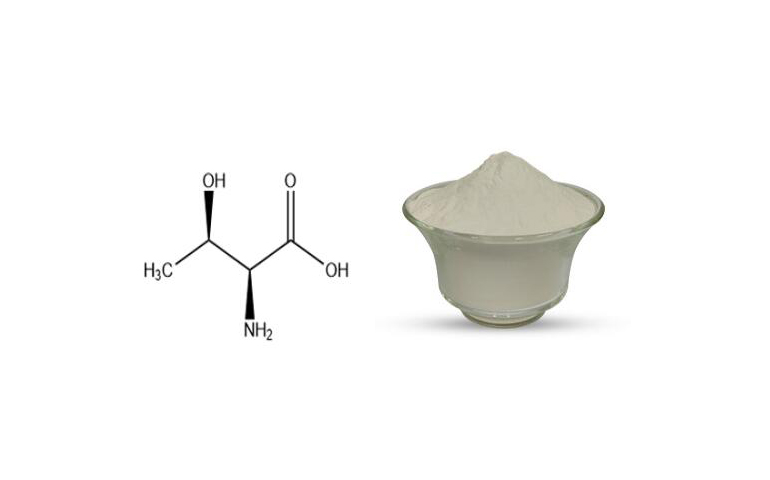

Glutamic Acid

COFCO Technology & Industry Technical Advantages

Innovations in Enzymatic Processes

High Purity and Green Production: Utilizing dual-enzyme cascade technology to significantly reduce byproduct formation, aligning with international environmental standards.

Breakthrough in Immobilization Technology: Employing magnetic nano-carriers to enable enzyme reuse, promoting continuous production and reducing overall energy consumption.

Innovations in Synthetic Biology

Strain Optimization: Using gene-editing technologies (e.g., CRISPR) to enhance Corynebacterium glutamicum, improving acid production efficiency and substrate utilization.

Multi-Enzyme Synergy: Developing multi-enzyme cascade systems, such as semi-synthetic artemisinin production, to expand the manufacturing of high-value derivatives (e.g., D-pyroglutamic acid).

Circular Economy Integration

Resource Utilization: Converting fermentation waste liquid into bacterial cellulose production, achieving wastewater COD reduction and resource regeneration.

High Purity and Green Production: Utilizing dual-enzyme cascade technology to significantly reduce byproduct formation, aligning with international environmental standards.

Breakthrough in Immobilization Technology: Employing magnetic nano-carriers to enable enzyme reuse, promoting continuous production and reducing overall energy consumption.

Innovations in Synthetic Biology

Strain Optimization: Using gene-editing technologies (e.g., CRISPR) to enhance Corynebacterium glutamicum, improving acid production efficiency and substrate utilization.

Multi-Enzyme Synergy: Developing multi-enzyme cascade systems, such as semi-synthetic artemisinin production, to expand the manufacturing of high-value derivatives (e.g., D-pyroglutamic acid).

Circular Economy Integration

Resource Utilization: Converting fermentation waste liquid into bacterial cellulose production, achieving wastewater COD reduction and resource regeneration.

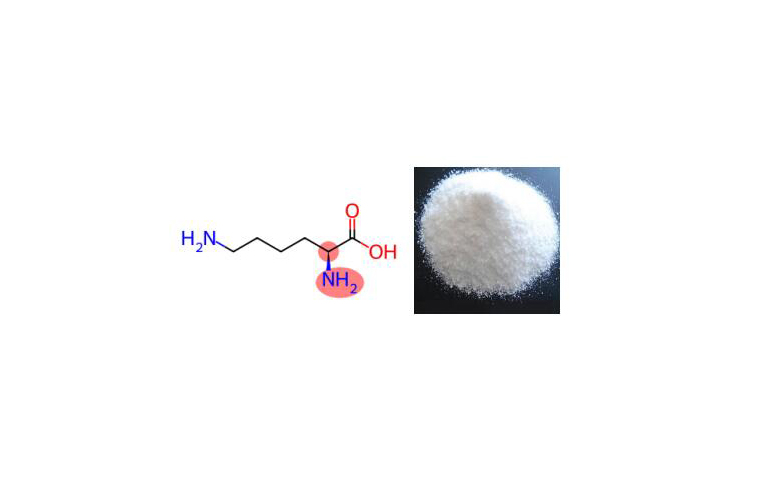

Lysine production project

You Might Also Be Interested In

Related Products

You Are Welcome To Consult Our Solutions, We Will Communicate With You In Time And Provide

Professional Solutions

Full Lifecycle Service

We provide customers with full life cycle engineering services such as consulting, engineering design, equipment supply, engineering operation management, and post renovation services.

We're Here to Help.

Frequently Asked Questions

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories.

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements.

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies.

Inquiry