Steel Silo

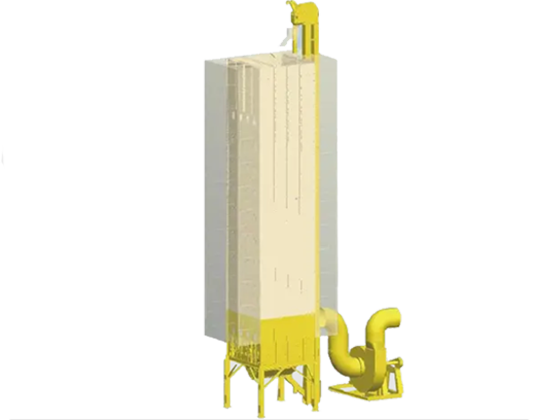

Small Circulating Dryer

The multi-layer angular air inlet and outlet structure can be installed and used in multiple sections. It can effectively remove moisture from grains. Batch processing capacity: 10t/d~50t/d; Precipitation rate: 0.8%/h~1.5%/h; Materials: Suitable for corn, wheat, rice, soybeans, rapeseed, seeds, etc.

SHARE :

Product Features

The angularly intersecting drying ducts enable thorough contact between the drying medium and the grain for uniform and rapid moisture removal;

The arrangement allows higher drying temperatures and thermal efficiency. Variable-frequency fans, automatic temperature control and multiple drying modes provide flexibility;

By eliminating inlet and outlet augers, mechanical damage to grains during drying is minimized. Reduced power equipment also ensures stable operation;

Suitable for paddy rice, wheat, corn, oilseeds and more, our dryers deliver versatility, efficiency and quality for grain drying.

Contact us for questions of our company, products or services

Learn More

Contact Form

COFCO Technology & Industry Co. Ltd.

We're Here to Help.

Frequently Asked Questions

We are providing information for both those familiar with our service and those that are new to COFCO Technology & Industry.

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories. View More

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements. View More

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies. View More