Steel Silo

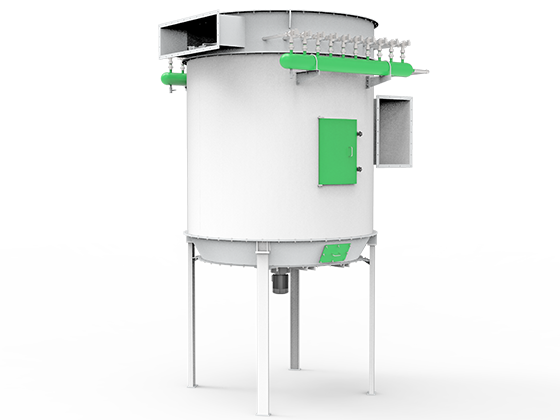

Pulse Dust Filter

TBLM Pulse Dust Filter is a kind of environment-friendly equipment, it can be widely used for air and dust separation of dusty air with temperature lower than 80 ℃.

SHARE :

Product Features

Low resistance

Gigh dust removal efficiency

Easy operation

Simple maintenance

Contact us for questions of our company, products or services

Learn More

Specification

| Category | Model | Filter Area (㎡) | Air Volume(m³/h) | Remark |

| Circular Pulse Dust Filter | TBLMA28 | 19.6 | 2350-4700 | Cone bottom |

| TBLMA40 | 28.2 | 3380-6760 | Cone bottom | |

| TBLMA52 | 36.7 | 4400-8800 | Cone bottom | |

| TBLMA78 | 55.1 | 6610-13220 | Flat, Cone bottom | |

| TBLMA104 | 73.4 | 8810-17620 | Flat, Cone bottom | |

| TBLMA132 | 93.2 | 11180-22360 | Flat, Cone bottom | |

| Square Pulse Dust Filter | TBLMF128 | 90.4 | 10850-21700 | Double air lock |

| TBLMF168 | 118.6 | 14230-28460 | screw conveyor ash discharge | |

| Pulse Dust Filter for Grain Unloading Pit (Including Intelligent) | TBLMX24 | 16.9 | 2030-4060 | |

| TBLMX36 | 25.4 | 3050-6100 | Intelligent, non-intelligent | |

| TBLMX48 | 33.9 | 4070-8140 | Intelligent, non-intelligent |

Contact Form

COFCO Technology & Industry Co. Ltd.

We're Here to Help.

Frequently Asked Questions

We are providing information for both those familiar with our service and those that are new to COFCO Technology & Industry.

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories. View More

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements. View More

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies. View More