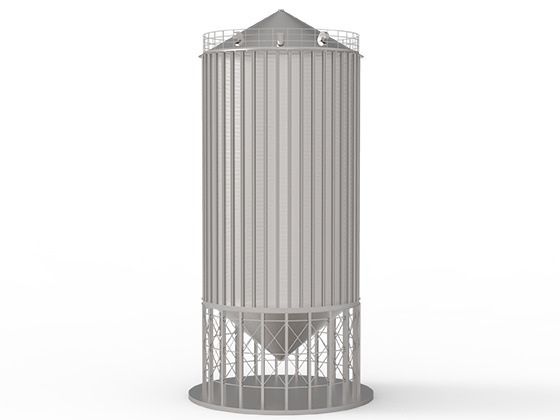

Steel Silo

Hopper Silo

Hopper bottom silo is constructed on a steel-frame structure, the stored material inside the silo is isolated from the ground which can preventing humidity, and stored material can be discharged easily through it’s self flow. Hopper bottom silo is widely used in poultry farm, rice mill, flour mill, soybean-oil mill, animal feed mill plant and brewery plant.

SHARE :

Product Features

Max Volume: 1,500MT (0.75t/m³)

Max Diameter: 11m

Hopper Angle: 45°, 55°

Steel Grade (Stamps): S350GD

Coating: Z275, Z350, Z450, Z600 and “310g/㎡ Magnesium+Aluminum+Zinc”

8.8 Grade Bolt

Contact us for questions of our company, products or services

Learn More

Specification

Specifications of 45°hopper silo

Noted:The capacity listed in the table includes silo top,silo and hopper bottom,which is caculated according to the unite weight of wheat 0.77t/m³.

Specifications of 55°hopper silo

Noted:The capacity listed in the table includes silo top,silo and hopper bottom,which is caculated according to the unite weight of wheat 0.77t/m³.

| Model | Volume(m3) | Capacity(t) | Sheet×ring | Height (m) | ||

| ring beam height | eaves height | full height | ||||

| 1.8 Series (Φ1834) | ||||||

| 1.8×2c | 7.2 | 5.5 | 2×2 | 1.76 | 4.055 | 4.47 |

| 1.8×3c | 10 | 7.7 | 2×3 | 5.175 | 5.59 | |

| 1.8×4c | 13 | 10 | 2×4 | 6.295 | 6.71 | |

| 2.7 Series (Φ2751) | ||||||

| 2.7×2c | 17 | 13 | 3×2 | 2.22 | 4.515 | 5.14 |

| 2.7×3c | 24 | 18 | 3×3 | 5.635 | 6.26 | |

| 2.7×4c | 31 | 23 | 3×4 | 6.755 | 7.38 | |

| 2.7×5c | 37 | 28 | 3×5 | 7.875 | 8.5 | |

| 3.6 Series (Φ3668) | ||||||

| 3.6×2c | 33 | 25 | 4×2 | 2.69 | 4.985 | 5.83 |

| 3.6×3c | 45 | 34 | 4×3 | 6.105 | 6.95 | |

| 3.6×4c | 56 | 43 | 4×4 | 7.225 | 8.07 | |

| 3.6×5c | 68 | 52 | 4×5 | 8.345 | 9.19 | |

| 3.6×6c | 80 | 61 | 4×6 | 9.465 | 10.31 | |

| 3.6×7c | 92 | 70 | 4×7 | 10.585 | 11.43 | |

| 4.5 Series (Φ4585 ) | ||||||

| 4.5×3c | 73 | 56 | 5×3 | 3.19 | 6.605 | 7.66 |

| 4.5×4c | 92 | 70 | 5×4 | 7.725 | 8.78 | |

| 4.5×5c | 111 | 85 | 5×5 | 8.845 | 9.9 | |

| 4.5×6c | 129 | 99 | 5×6 | 9.965 | 11.02 | |

| 4.5×7c | 148 | 114 | 5×7 | 11.085 | 12.14 | |

| 4.5×8c | 166 | 127 | 5×8 | 12.205 | 13.26 | |

| 4.5×9c | 185 | 142 | 5×9 | 13.325 | 14.38 | |

| 5.5 Series (Φ5500 ) | ||||||

| 5.5×4c | 138 | 106 | 6×4 | 3.62 | 8.155 | 9.42 |

| 5.5×5c | 165 | 127 | 6×5 | 9.275 | 10.54 | |

| 5.5×6c | 192 | 148 | 6×6 | 10.395 | 11.66 | |

| 5.5×7c | 218 | 168 | 6×7 | 11.515 | 12.78 | |

| 5.5×8c | 245 | 188 | 6×8 | 12.635 | 13.9 | |

| 5.5×9c | 272 | 209 | 6×9 | 13.755 | 15.02 | |

| 5.5×10c | 298 | 229 | 6×10 | 14.875 | 16.14 | |

| 6.4 Series (Φ6420 ) | ||||||

| 6.4×5c | 231 | 177 | 7×5 | 4.07 | 9.725 | 11.21 |

| 6.4×6c | 267 | 205 | 7×6 | 10.845 | 12.33 | |

| 6.4×7c | 303 | 233 | 7×7 | 11.965 | 13.45 | |

| 6.4×8c | 339 | 261 | 7×8 | 13.085 | 14.57 | |

| 6.4×9c | 375 | 288 | 7×9 | 14.205 | 15.69 | |

| 6.4×10c | 411 | 316 | 7×10 | 15.325 | 16.81 | |

| 6.4×11c | 447 | 344 | 7×11 | 16.445 | 17.93 | |

| 7.3 Series (Φ7334 ) | ||||||

| 7.3×5c | 314 | 241 | 8×5 | 10.185 | 11.88 | |

| 7.3×6c | 361 | 277 | 8×6 | 11.305 | 13 | |

| 7.3×7c | 408 | 314 | 8×7 | 4.53 | 12.425 | 14.12 |

| 7.3×8c | 455 | 350 | 8×8 | 13.545 | 15.24 | |

| 7.3×9c | 503 | 387 | 8×9 | 14.665 | 16.36 | |

| 7.3×10c | 550 | 423 | 8×10 | 15.785 | 17.48 | |

| 7.3×11c | 597 | 459 | 8×11 | 16.905 | 18.6 | |

| 7.3×12c | 644 | 495 | 8×12 | 18.025 | 19.72 | |

| 7.3×13c | 692 | 532 | 8×13 | 19.145 | 20.84 | |

| 8.2 Series (Φ8254) | ||||||

| 8.2×6c | 468 | 360 | 9×6 | 4.98 | 11.755 | 13.66 |

| 8.2×7c | 528 | 406 | 9×7 | 12.875 | 14.78 | |

| 8.2×8c | 588 | 452 | 9×8 | 13.995 | 15.9 | |

| 8.2×9c | 648 | 498 | 9×9 | 15.115 | 17.02 | |

| 8.2×10c | 708 | 545 | 9×10 | 16.235 | 18.14 | |

| 8.2×11c | 768 | 591 | 9×11 | 17.355 | 19.26 | |

| 8.2×12c | 828 | 637 | 9×12 | 18.475 | 20.38 | |

| 8.2×13c | 888 | 683 | 9×13 | 19.595 | 21.5 | |

| 8.2×14c | 948 | 729 | 9×14 | 20.715 | 22.62 | |

| 9.1 Series (Φ9167 ) | ||||||

| 9.1×7c | 666 | 512 | 10×7 | 5.43 | 13.325 | 15.45 |

| 9.1×8c | 740 | 569 | 10×8 | 14.445 | 16.57 | |

| 9.1×9c | 813 | 626 | 10×9 | 15.565 | 17.69 | |

| 9.1×10c | 886 | 682 | 10×10 | 16.685 | 18.81 | |

| 9.1×11c | 960 | 739 | 10×11 | 17.805 | 19.93 | |

| 9.1×12c | 1034 | 796 | 10×12 | 18.925 | 21.05 | |

| 9.1×13c | 1108 | 853 | 10×13 | 20.045 | 22.17 | |

| 9.1×14c | 1182 | 910 | 10×14 | 21.165 | 23.29 | |

| 10.0 series (Φ10089) | ||||||

| 10.0×8c | 914 | 703 | 11×8 | 5.89 | 14.905 | 17.24 |

| 10.0×9c | 1003 | 772 | 11×9 | 16.025 | 18.36 | |

| 10.0×10c | 1092 | 840 | 11×10 | 17.145 | 19.48 | |

| 10.0×11c | 1181 | 909 | 11×11 | 18.265 | 20.6 | |

| 10.0×12c | 1271 | 978 | 11×12 | 19.385 | 21.72 | |

| 10.0×13c | 1360 | 1047 | 11×13 | 20.505 | 22.84 | |

| 10.0×14c | 1449 | 1115 | 11×14 | 21.625 | 23.96 | |

| 10.0×15c | 1539 | 1185 | 11×15 | 22.745 | 25.08 | |

| 11.0 series (Φ11001 ) | ||||||

| 11.0×8c | 1112 | 856 | 12×8 | 6.33 | 15.345 | 17.89 |

| 11.0×9c | 1218 | 937 | 12×9 | 16.465 | 19.01 | |

| 11.0×10c | 1324 | 1019 | 12×10 | 17.585 | 20.13 | |

| 11.0×11c | 1430 | 1101 | 12×11 | 18.705 | 21.25 | |

| 11.0×12c | 1536 | 1182 | 12×12 | 19.825 | 22.37 | |

| 11.0×13c | 1643 | 1265 | 12×13 | 20.945 | 23.49 | |

| 11.0×14c | 1749 | 1346 | 12×14 | 22.065 | 24.61 | |

| 11.0×15c | 1855 | 1428 | 12×15 | 23.185 | 25.73 | |

Noted:The capacity listed in the table includes silo top,silo and hopper bottom,which is caculated according to the unite weight of wheat 0.77t/m³.

Specifications of 55°hopper silo

| Model | Volume(m3) | Capacity(t) | Sheet×ring | Height (m) | ||

| ring beam height | eaves height | full height | ||||

| 1.8 Series (Φ1834) | ||||||

| 1.8×2c | 7.5 | 5.8 | 2×2 | 2.09 | 4.395 | 4.81 |

| 1.8×3c | 10.5 | 8.1 | 2×3 | 5.515 | 5.93 | |

| 1.8×4c | 13.4 | 10.3 | 2×4 | 6.635 | 7.05 | |

| 2.7 Series (Φ2751) | ||||||

| 2.7×2c | 18 | 13 | 3×2 | 2.75 | 5.055 | 5.68 |

| 2.7×3c | 25 | 19 | 3×3 | 6.175 | 6.8 | |

| 2.7×4c | 32 | 24 | 3×4 | 7.295 | 7.92 | |

| 2.7×5c | 39 | 30 | 3×5 | 8.415 | 9.04 | |

| 3.6 Series (Φ3668) | ||||||

| 3.6×2c | 36 | 27 | 4×2 | 3.61 | 5.905 | 6.75 |

| 3.6×3c | 48 | 37 | 4×3 | 7.025 | 7.87 | |

| 3.6×4c | 60 | 46 | 4×4 | 8.145 | 8.99 | |

| 3.6×5c | 72 | 55 | 4×5 | 9.265 | 10.11 | |

| 3.6×6c | 84 | 64 | 4×6 | 10.385 | 11.23 | |

| 4.5 Series (Φ4585 ) | ||||||

| 4.5×3c | 80 | 61 | 5×3 | 4.04 | 10.645 | 11.7 |

| 4.5×4c | 98 | 75 | 5×4 | 11.765 | 12.82 | |

| 4.5×5c | 116 | 89 | 5×5 | 12.885 | 13.94 | |

| 4.5×6c | 134 | 103 | 5×6 | 14.005 | 15.06 | |

| 4.5×7c | 152 | 117 | 5×7 | 15.125 | 12.18 | |

| 4.5×8c | 170 | 131 | 5×8 | 16.245 | 16.18 | |

| 5.5 Series (Φ5500 ) | ||||||

| 5.5×4c | 148 | 114 | 6×4 | 4.7 | 9.235 | 10.5 |

| 5.5×5c | 175 | 134 | 6×5 | 10.355 | 11.62 | |

| 5.5×6c | 202 | 155 | 6×6 | 11.475 | 12.74 | |

| 5.5×7c | 229 | 176 | 6×7 | 12.595 | 13.86 | |

| 5.5×8c | 256 | 197 | 6×8 | 13.715 | 14.98 | |

| 5.5×9c | 283 | 218 | 6×9 | 14.835 | 16.1 | |

| 5.5×10c | 310 | 238 | 6×10 | 15.955 | 18.36 | |

| 6.4 Series (Φ6420 ) | ||||||

| 6.4×5c | 248 | 190 | 7×5 | 5.37 | 11.025 | 12.51 |

| 6.4×6c | 284 | 218 | 7×6 | 12.145 | 13.63 | |

| 6.4×7c | 320 | 246 | 7×7 | 13.265 | 14.75 | |

| 6.4×8c | 356 | 274 | 7×8 | 14.385 | 15.87 | |

| 6.4×9c | 393 | 302 | 7×9 | 15.505 | 16.99 | |

| 6.4×10c | 429 | 330 | 7×10 | 16.625 | 18.11 | |

| 6.4×11c | 465 | 358 | 7×11 | 17.745 | 19.23 | |

| 7.3 Series (Φ7334 ) | ||||||

| 7.3×5c | 334 | 257 | 8×5 | 11.655 | 13.35 | |

| 7.3×6c | 381 | 293 | 8×6 | 12.775 | 14.47 | |

| 7.3×7c | 428 | 330 | 8×7 | 6 | 13.895 | 15.59 |

| 7.3×8c | 475 | 366 | 8×8 | 15.015 | 16.71 | |

| 7.3×9c | 522 | 402 | 8×9 | 16.135 | 17.83 | |

| 7.3×10c | 569 | 438 | 8×10 | 17.255 | 18.95 | |

| 7.3×11c | 616 | 474 | 8×11 | 18.375 | 20.07 | |

| 7.3×12c | 663 | 510 | 8×12 | 19.495 | 21.19 | |

| 7.3×13c | 710 | 546 | 8×13 | 20.615 | 22.31 | |

| 8.2 Series (Φ8254) | ||||||

| 8.2×6c | 501 | 385 | 9×6 | 6.67 | 13.445 | 15.35 |

| 8.2×7c | 561 | 432 | 9×7 | 14.565 | 16.47 | |

| 8.2×8c | 621 | 478 | 9×8 | 15.685 | 17.59 | |

| 8.2×9c | 681 | 524 | 9×9 | 16.805 | 18.71 | |

| 8.2×10c | 741 | 570 | 9×10 | 17.925 | 19.83 | |

| 8.2×11c | 801 | 616 | 9×11 | 19.045 | 20.95 | |

| 8.2×12c | 861 | 663 | 9×12 | 20.165 | 22.07 | |

| 8.2×13c | 921 | 709 | 9×13 | 21.285 | 23.19 | |

| 8.2×14c | 981 | 755 | 9×14 | 22.405 | 24.31 | |

Noted:The capacity listed in the table includes silo top,silo and hopper bottom,which is caculated according to the unite weight of wheat 0.77t/m³.

Contact Form

COFCO Technology & Industry Co. Ltd.

We're Here to Help.

Frequently Asked Questions

We are providing information for both those familiar with our service and those that are new to COFCO Technology & Industry.

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories. View More

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements. View More

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies. View More