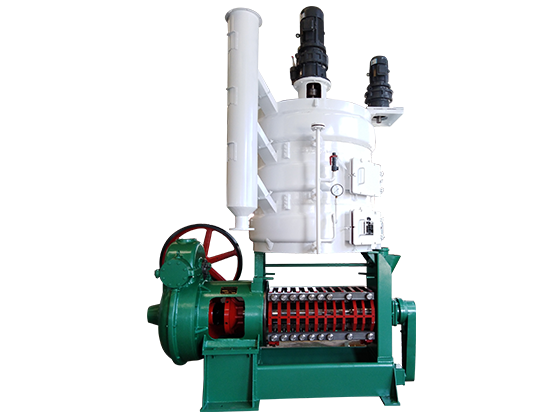

Product Features

Good wear resistance and long service life of wearing parts

Lower oil in cake rate

Forced feeding, increase capacity

Strengthen the steam cooker structure and extend the service life

Contact us for questions of our company, products or services

Learn More

Specification

| Capacity | Oil in cake | Power | Overall dimensions (LxWxH) | N.W |

| 6-8 t/d | 10-12 % | 18.5(15)+7.5+3.0 kW | 2900x1850x3240 mm | 5500 kg |

Note:Above parameters are for reference only. The capacity, oil in cake, power etc. will vary with different raw materials and process conditions

Contact Form

COFCO Technology & Industry Co. Ltd.

We're Here to Help.

Frequently Asked Questions

We are providing information for both those familiar with our service and those that are new to COFCO Technology & Industry.

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories. View More

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements. View More

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies. View More