Product Features

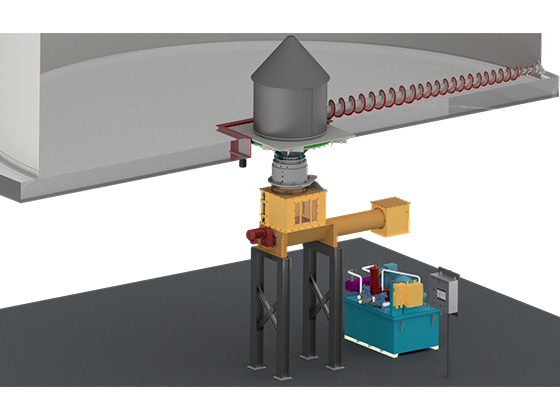

The head cover adopts DEM (Discrete Element Method) optimization, which is designed as a parabolic shape according to the material throwing characteristics to reduce the material return;

The discharge outlet is set with adjustable plate to reduce the material return;

Protective cover and rubber sealing ring are added to the bearing to increase safety and improve bearing life;

The drive shaft is sealed specially for good sealing effect and easy maintenance;

The tail has an option of the self-cleaning design base to effectively reduce material residue;

A cleaning door and a return hopper are arranged on the base of the bucket elevator.

Contact us for questions of our company, products or services

Learn More

Specification

| Model | Speed (m/s) | Capacity/wheat (t/h) |

| TDTG60/33 | 2.5-3.5 | 100-150 |

| TDTG60/46 | 2.5-3.5 | 120-200 |

| TDTG80/46 | 2.5-3.5 | 160-240 |

| TDTG80/56 | 2.5-3.5 | 200-310 |

| TDTG80/46×2 | 2.5-3.5 | 320-480 |

| TDTG100/56×2 | 2.5-3.5 | 500-650 |

| TDTG120/56×3 | 2.5-3.5 | 750-1100 |

Contact Form

COFCO Technology & Industry Co. Ltd.

We're Here to Help.

Frequently Asked Questions

We are providing information for both those familiar with our service and those that are new to COFCO Technology & Industry.

-

CIP Cleaning System+CIP cleaning system device is a non-decomposable production equipment and a simple and safe automatic cleaning system. It is used in almost all food, beverage and pharmaceutical factories. View More

-

A Guide to Pressed and Extracted Oils+There are significant differences between the pressed oil and extracted oil in terms of processing techniques, nutritional content, and raw material requirements. View More

-

Scope of Technical Service for Grain-based Biochemical Solution+At the core of our operations are internationally advanced strains, processes, and production technologies. View More